Introduction:

Rigid-laid (also referred to a "bound construction") for block pavers is not commonly used, as it requires a much higher level of skill from the installation team, and it is more expensive to construct, in terms of both labour and materials.

The majority of brick paving in Britain and Ireland is laid as a flexible pavement and rigid paving is normally used for special applications, usually commercial. Typical uses of rigid rather than flexible paving include....

- Areas that must have a sealed floor for hygiene or other reasons

- Areas subjected to frequent surface water flows, such as vehicle washing areas

- For the aesthetic appeal of mortar joints

- To complement external flexible paved areas in an interior setting, eg foyers, reception areas, etc.

- Decorative work

Rigid brick pavements often require movement joints and therefore need to be designed and constructed by professionals, and are not suited to DIY, unless you are skilled in bricklaying. If you employ a paving company to construct a rigid brick pavement on your behalf, make sure that you inspect similar work they have previously undertaken. The skills required for constructing a rigid pavement are not the same as those skills used in flexible paving construction.

There should be 5 layers to all rigid brick paving installations, but this can be reduced to 4 depending on planned usage. Low-traffic or pedestrian-only pavements may omit the sub-base.

These layers are, from top to base...

- Paving or Surface Layer

- Bedding or Laying Course

- Base Course

- Sub-base - optional

- Sub-grade

Most brick pavers for rigid paving are 65mm thick, although there are 50mm thick versions suitable for residential projects such as patios and driveways. Some manufacturers also produce 30-40mm thick 'bricks' for internal applications. These products sit on the borderline between bricks and tiles.

Preparation

See also Setting Out page

Decide where you want the paving to run, and mark out with sand guide-lines, if required. It is assumed that the paving is to be flush i.e. level, with the existing ground. It is a good idea to dig wider than the planned paving width, allowing an extra 75-100mm at the edges makes handling much easier.

Sub-grade

See also sub-grades page

The surface needs to be dug off to a depth of approx. 250-400mm. The depth of dig can be roughly calculated as.....

(depth of pavers + 30mm bedding + 150mm base + 150mm sub-base*)

Remove all weeds and other unwanted organic matter. Excavate any soft spots and fill with compacted sub-base material. If the area of the paving is troubled with weeds, you may treat the excavated sub-grade with a general weedkiller such as Glyphosate, but it is unlikely any normal weed will be able to penetrate the upper layers.

Base Layer

This is essential beneath all rigid pavements and must be constructed from a bound material. A bound material is one that becomes monolithic, ie, all one unit, when set. In 99% of cases this means bitmac or concrete.

An existing bitmac, asphalt or concrete surface can be used provided that it is in good condition, not cracked, not subject to settlement or movement and will not compromise any damp-proof courses once the paving is laid. Any base being used in this way should be cleaned, preferably with a power washer to remove all vegetation and organic matter before placing the bedding layer.

Under no circumstances is a un-bound sub-base acceptable in place of this base; a sub-base of loose or granular material, such as compacted earth, crushed stone etc, continues to move over time, and would cause cracking of the rigid paving and bedding layers. There may be a flexible sub-base beneath the base layer in high traffic projects.

A 75-150mm thick base layer is the usual specification. If a bitmac or asphalt base is to be used, this will need to be laid over a prepared sub-base, typically 150mm thick. If a concrete base layer is specified, this should be laid on a damp proof membrane (dpm) over a 150mm thick compacted sub-base, or may be laid, again on a dpm, over the prepared sub-grade. A concrete of minimum strength C20 should be used, reinforcing steel is only required in suspect ground or high-load applications.

If a sub-base is required this should be constructed as shown on the sub-bases page.

Movement Joints

To control any movement of the solid base layer, it is essential that movement joints are constructed within the base layer and surface layers at intervals of not more than 6 metres. These movement joints should extend through the base layer to the surface of the paving layer as shown in the construction diagram opposite. Movement joints should also be constructed to isolate any fixtures, such as manhole covers, lighting columns etc.

Bedding layer

The bedding material should be a Class 1 mortar , stiff, but retaining it's plasticity. The usual mix for the bedding mortar is 1:¼:3 - cement:lime:sand. On some projects the lime is replaced by a proprietary plasticising agent.

Paving Layer

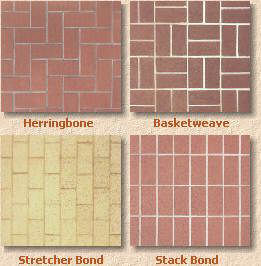

The base layer should be doused with water before placing mortar to prevents the Base layer from sucking the water out of the mortar, rendering it too stiff to bed the pavers correctly. The mortar is spread over the dampened base layer approximately 20-35mm thick, and is 'rippled' with the blade of a trowel to allow the paver to be bedded into the mortar. If working in courses, it is usual to lay out sufficient mortar to complete one course at a time. With other patterns the mortar may be spread out at approx 1m² at a time to ensure the bed is still 'fresh' when the pavers are positioned. The paving bricks or blocks should be laid to a specific pattern. If you are using more than 1 pack of blocks, mix the pavers by drawing them from 3 or 4 packs simultaneously, to ensure there is no banding or spotting of certain shades within the pavement. This is very important with multi-coloured blocks, such as the ever popular multi-red described as 'Brindle'.

A taut string line should be established as a guide to line and level for each course or section of paving. A camber can be created by working to a template or profile cut from timber. The guide line should be moved along as the laying proceeds, and the use of a straight-edge rule over freshly laid work will help ensure that levels are kept within tolerance and no unsightly dips or humps appear in the finished pavement.

One end and the bottom of each paver is buttered with the jointing mortar and pressed into the bedding mortar and up against the preceding course or edge, squeezing the mortar up in the joint. Any excess mortar should be removed with the trowel immediately.

Bricks that need to be cut to fit in at edges should be placed as the work proceeds, and not left until the rest of the pavers are laid, as the bedding mortar will be 'stale' and difficult to replace. Clay pavers are notoriously difficult to cut with a conventional block splitter and are best cut with a diamond-tipped blade on a bench mounted power saw.

Kerbs

If you require a kerb, It can be constructed as the work progresses or added once the body of the paving has set. Almost any solid element can be used to form a kerb. Stone cobbles, road kerbs, concrete edgings are all fine; the complementary kerb units are relatively expensive, but do add that finishing touch, or a simple paver laid on edge or on end could be used. They should be laid on a mortar bed as the pavers are and haunched with concrete.

See also Edgings & Kerbs

Jointing/Sealing

The jointing is usually completed as the work progresses, using the same mix as used for the bedding layer although it is usual to strengthen the mortar with a SBR agent (Styrene Butadiene) at the recommended dose. This improves the bonding of the jointing mortar, renders it waterproof and hardens the surface to minimise damage to the joints from foot traffic.

The jointing mortar is packed into the joints, the surplus removed and the joint smoothed with a jointing tool. The typical joint profile for a rigid pavement is bucket-handle (concave).

See Pointing and Jointing page for guidance on mortar pointing of a pavement.

2-4 hours after pointing, the surface should be swept with a soft brush to remove any mortar 'snots', although care must be taken to avoid disturbing the mortar jointing.

Any movement joints should be sealed with a suitable flexible but non-tacky sealant, such as polysulphide or silicone, and should be kept free from all traffic for 48-72 hours minimum while the mortar and movement joint sealant cure.

Final Cleaning

It is well-nigh impossible to keep a rigid pavement completely clean and free from mortar stains during the construction progress, no matter how much care the tradesman takes. Most mortar stains will be relatively minor and may disappear by weathering in a matter of weeks, but it is usual to clean the area with a weak (4-7%) hydrochloric acid wash 6-12 weeks after completion. Care must be taken when using these washes or the acid will attack and degrade the mortar jointing. Pavements to be cleaned should be thoroughly soaked with clean water prior to applying the wash. This clean water 'saturates' the mortar joints, which reduces the amount of acid that can be drawn into the mortar during cleaning, thereby reducing the risk of joint damage. It is essential to thoroughly rinse the pavement with clean water 10-20 minutes the wash has been applied, and care should be taken to avoid acidic run-off splashing vulnerable paintwork or planted areas.