Introduction:

Self-Binding Gravels from Breedon Special Aggregates, part of the Breedon Group, are naturally occurring aggregates, making them eminently sympathetic to gardens, rural settings or anywhere a more informal or naturalistic finish is required, while its self-setting characteristics make it ideal for pedestrian and light vehicular traffic usage. More reliable and better behaved than loose gravel chippings, but considerably cheaper and less of a man-made look than is possible with resin- or bitumen-bound surfacing.

A self-binding gravel is usually regarded as more dependable and having lower maintenance requirements compared to a gravel, but its construction is very similar, in that’s it’s simple and straightforward. It can be installed by any paving professional, but is well within the capabilities of most landscapers, builders and even a competent DIYer.

Overall, self-binding gravels are an incredibly versatile surfacing option offering a low-cost yet reliable surface for all sorts of projects.

The Advantages:

- Naturalistic and informal appearance

- Low cost

- Ease of installation by semi-skilled operatives

- Ease of maintenance

- Overall versatility

- Suitable for pedestrian and light vehicular use

What it is:

Self-binding gravels rely on a combination of fines (particles smaller than 1mm) and slightly larger aggregate, up to around 12-14mm. The principle is simple: the fine material envelops the larger aggregate and holds it in place.

Many self-binding gravels are based around a limestone aggregate, in which the calcareous content (limestone is predominantly Calcium Carbonate) acts as a natural, albeit relatively weak, cement.

This page considers two subtly different self-binding gravels produced by the country’s leading supplier of such aggregates, Breedon Special Aggregates.

Breedon Golden Amber Gravel has been developed for those projects where pedestrians or light vehicular traffic will use the surface, while the finer Breedon Wayfarer Gravel is intended for foot traffic, bicycles, etc. only.

Both are non-susceptible to frost and therefore can be used all year round. Even better, both are considered to be wheelchair-friendly, and present no hazard to ambulant disabled people, either.

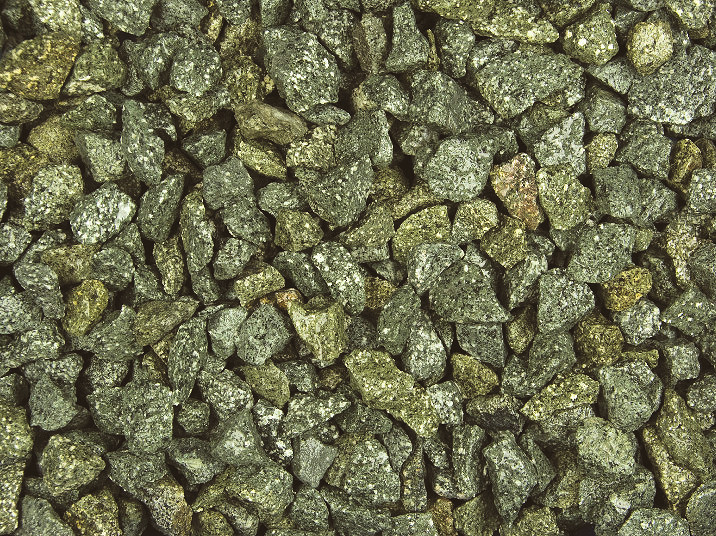

Breedon gravels originate in a single quarry tucked in between Derby and Loughborough in the English East Midlands, and almost on the border between Leicestershire and Derbyshire. Stone has been quarried here for centuries, for building, and for road and rail construction, but the particular characteristics of the crushed stone, with its all-important marl content, make it ideal for use as a self-binding gravel.

Such is the quality and performance record of Breedon aggregates that they have what some regard as the highest possible accolade: a Royal Warrant. Yes folks, you too can have the same Breedon Golden Amber gravel on your driveways as a certain someone has on their London gaff, popularly known as Buckingham Palace!

Both aggregates hail from the same bedrock and so they share the same, distinctive golden hue, but there are important differences which affect where each should be used for best results.

The most obvious difference is the particle size. Breedon Golden Amber Gravel is the flagship product and has the chunkier particle size, up to 12mm, which makes it ideally suited for those surfaces which will take vehicular traffic (at low speeds, obv!) Wayfarer is intended for use in pedestrian-only areas, so has a smaller size, up to a maximum of 6mm.

Despite the difference in aggregate size, the appearance when laid is remarkably similar – a fine, uniform, tight and appealing surface with a hint of loose, almost dusty material on the surface. Don’t be misled into thinking that, because these are gravels, there will be a loose, pebbly, stony finish. They are compact, smooth and densely finished.

Note that, when first laid, the surface naturally 'scarifies' to give a light dressing of loose chippings which prviodes that distinctive gravelly crunch.

Intended Applications:

Breedon Golden Amber Gravel

- Footpaths & Nature Trails

- Residential Driveways

- Car Parks

- Cycle Routes

- Bridleways

- Golf courses

- Canal Towpaths

- Parks, Leisure & Recreational

- Colleges & Universities

- Historical Settings

Wayfarer

- Footpaths & Nature Trails

- Cycle Routes

- Bridleways

- Golf courses & Sports

- Canal towpaths

- Leisure and recreational

Construction:

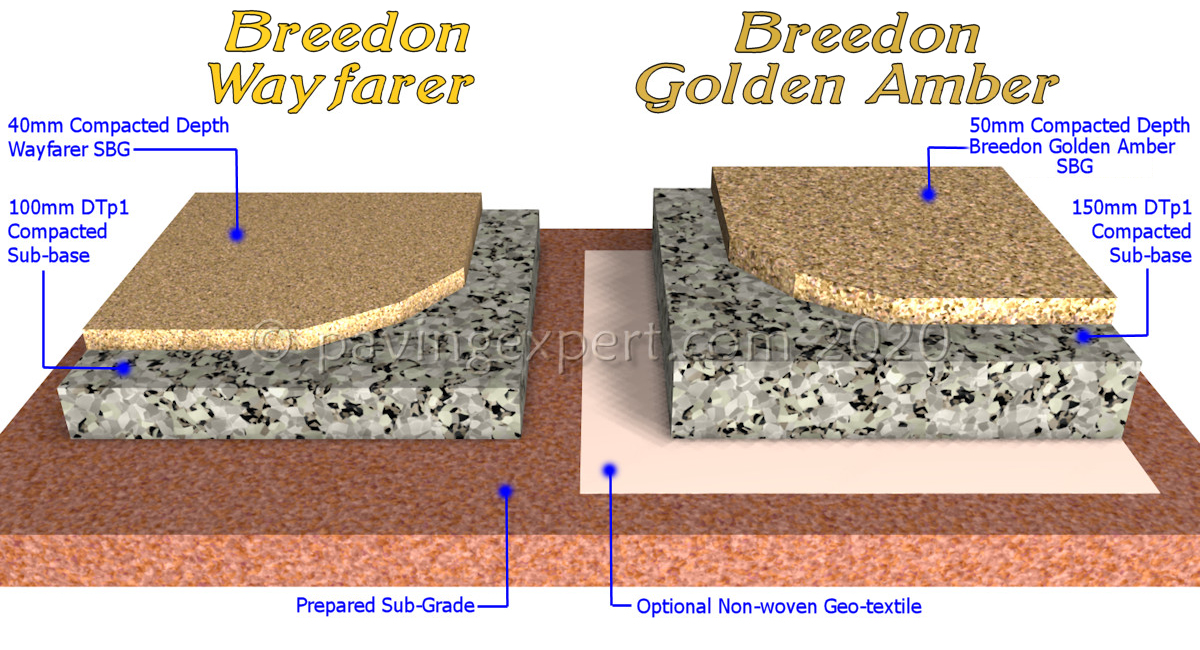

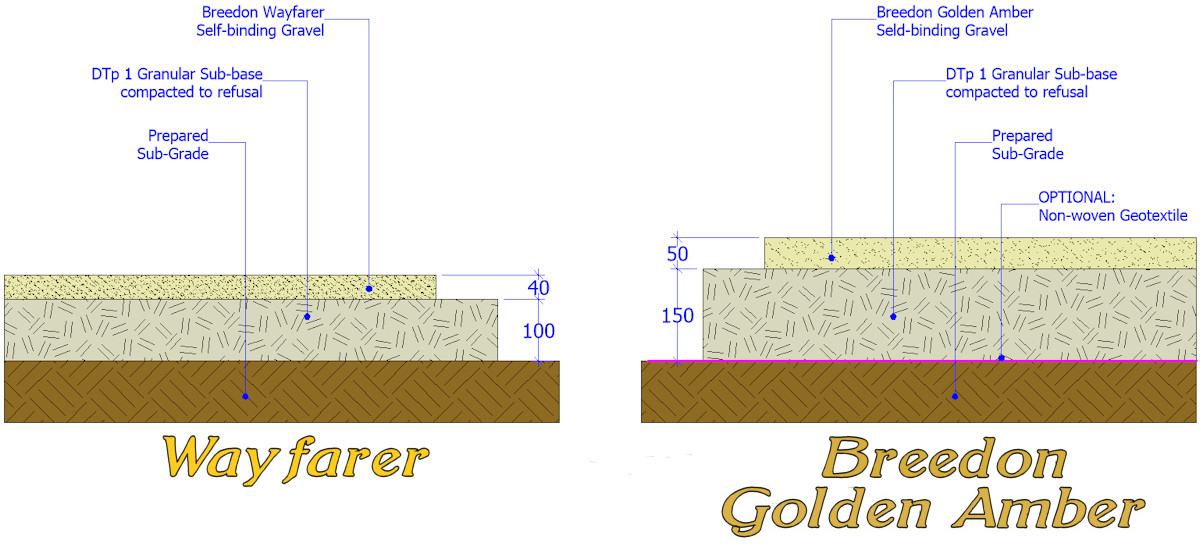

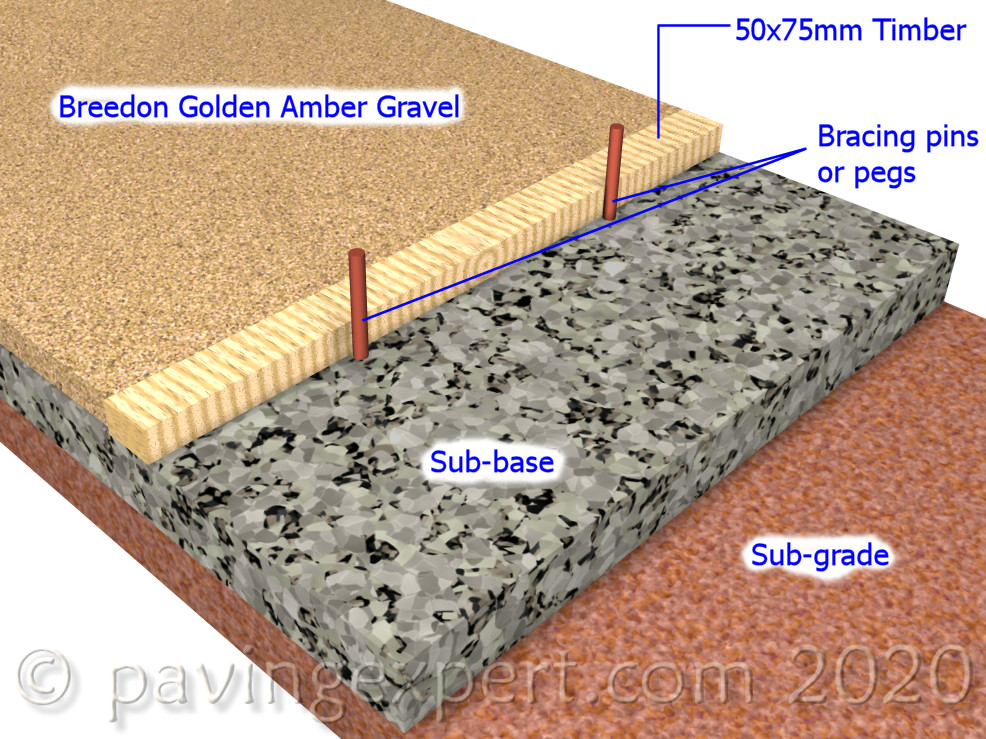

Both the Breedon Golden Amber Gravel and the Wayfarer are laid in much the same manner, and it’s very simple: a sound, reliable sub-base, and a top layer of the chosen self-binding aggregate. No need for a bound base layer, no over-riding insistence on edgings (although they can be added, if so desired.)

However, the unique characteristics of self-binding aggregates require a few basic rules to ensure the products perform to their best and keep maintenance to a minimum.

The sub-base MUST be somewhat permeable

It doesn’t need to be completely free-draining, as would a sub-base of clean or Type 3 aggregate, but it must offer the potential for water to pass through. A sub-base of Type 1 aggregate is perfect. The aggregates should not be laid over a base of macadam or concrete or any other solid, impermeable surface.

The sub-base must be thoroughly compacted.

Compaction to refusal is what’s required, that is, compaction to the point where the aggregate will not compact any further. It’s as well-compacted as it’s possible to be. This usually means a vibrating double drum roller will be needed.

Lightweight plate compactors of the type favoured by landscapers and builders are very unlikely to be suitable. However, if a “Wacker” type plate compactor has to be used, then it needs to be a larger type, minimum 75kg, preferably even heavier.

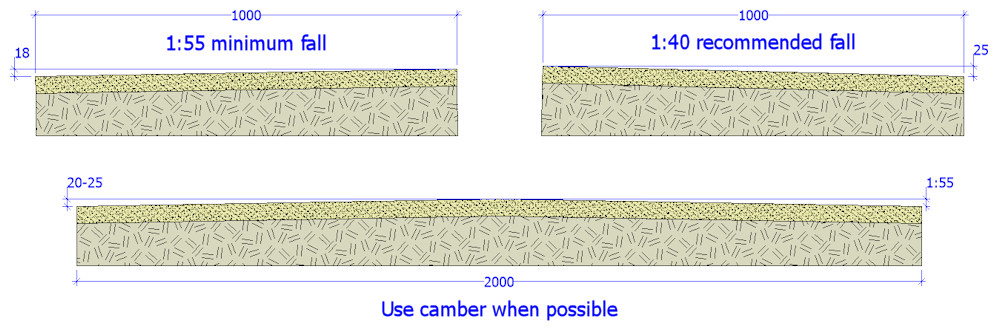

There must be adequate falls formed by the compacted sub-base

Don’t be fooled into believing (as some would have it) that a self-binding gravel is permeable or free-draining. It isn’t – well, at least not sufficiently so to be considered and used as a permeable material. Once laid, watered-rolled in and compacted, the Breedon self-binding gravels are *almost* impermeable, and so allowance must be made for surface drainage. The completed area must have a fall or slope that will efficiently carry away any surface water to a suitable drainage point.

If a geotextile is used, it must NOT be placed over the sub-base

Geotextiles can be a boon on poor, unstable or unreliable ground, but the only place for one to be used in this construction is between the prepared sub-grade and the sub-base. This enables it to perform as a true separation membrane between the ground beneath and the clean aggregate above.

If mistakenly placed between sub-base and the self-binding gravel, it would act as a slip membrane, preventing the Breedon Gravel embedding with the sub-base, which in turn makes it difficult to compact the self-binding gravels properly and this would encourage the formation of soft spots and potholes.

The self-binding aggregate must be spread with a lute or screeder board

....and not by the tines of a rake!

While it may seem a good idea to use a landscape or tarmacadam rake to spread and level the self-binding aggregate, the harrowing action of the tines (teeth/prongs) actually causes separation of the larger and fine particles, and, as already mentioned, it’s this mix of the particle sizes that cause the aggregate to be self-binding. Segregation leads to areas of ‘pebbles’ and other areas of fines, and that leads to trouble!

The aggregates MUST be laid to a fall

This follows on from the requirement for the sub-base to have a fall. Once compacted, the self-binding aggregate will behave as an impermeable surfacing. Some water will penetrate, of course, but most of it will run across the surface so a drainage plan is essential.

Generally speaking, aim for a fall of not less than 1:55 for narrow paths (2m or less) and 1:40 for larger areas such as courtyards or parking areas.

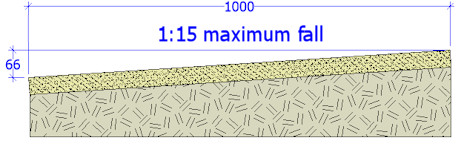

The aggregates must not be laid to a steep fall

Bear in mind that the binding action of the Breedon Golden Amber and the Wayfarer aggregates is not hard and fast, like a cement or bitumen binder. Heavy scour from excessive volumes of fast running water draining across the surface could erode the surface and cause it to start degrading, therefore water flow rates should be kept to a reasonable rate. Keeping falls to no more than 1:15 will help the surfacing resist scour and minimise any risk of degradation.

The follow-on from this is that neither Breedon Golden Amber nor Wayfarer should be used on slopes greater than 1:15. In such scenarios, a stepped or terraced solution can be employed to allow the use of self-binding aggregates.

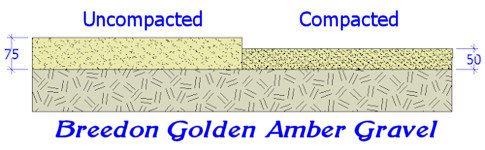

The aggregate usually compacts by around 50%

Projects using the Wayfarer aggregate should aim for a compacted thickness of 40mm, therefore the loose aggregate is applied to an uncompacted depth of around 60mm. Similarly, for projects using the larger Breedon Golden Amber gravel, a 50mm compacted thickness is recommended, therefore cover the sub-base with around 75mm of the loose aggregate.

Coverage rates

Wayfarer @ 40mm compacted thickness = c.10m²/tonne

Breedon Golden Amber @ 50mm compacted thickness = c.8m²/tonne

The levelled aggregate must be rolled and then wet-rolled

This cannot be overstated. Compaction of both Breedon Golden Amber and Wayfarer is a two-stage process that is critical to the longer-term performance of the surfacing.

Firstly, a double drum roller is used to thoroughly compact the aggregate in-situ. The vibratory action must be used to ensure full compaction, so several passes will be required.

Secondly, the critical wet-rolling process is undertaken. Wet-rolling brings the fines to the surface so that a tight, homogeneous and hard-wearing finish is achieved.

Wet-Rolling relies on applying water to the surface as it is rolled, so that the water can penetrate the aggregate and initiate the hardening process. No vibration is used during the wet-rolling process. Water is best applied by using the spray bars on the roller, so that a continuous feed of water is applied to the drums as they turn. In an ideal situation, the roller would be pushing a small wave of water ahead of it. It is usually necessary to apply additional water by spraying a hose onto the leading drum of the roller.

As a rough guide, around 20-25 litres of clean cold water per tonne of aggregate will be required. Other than in exceptionally narrow areas, it is unlikely that a typical contractors’ plate compactor would be capable of achieving full compaction.

If there is no option other than to use a plate compactor, a heavy plate of not less than 75kg mass should be used, and the coverage depth of the aggregate could be reduced slightly. For wet-compaction, water must be applied to the plate as it travels over the surface.

As mentioned above in regard to the compaction of the sub-base, using a vibrating plate compactor will be far more labour intensive, comnpared to a roller, as many more passes are required to achieve a satisfactory standard of finish to both the compaction stage and the watering-in stage.

Roller lines can be brushed out

Rollers have a habit of leaving travel lines in the surface they are compacting. These are usually minor ridges of a millimetre or so, but if left unaddressed, they could remain in place. They are easily removed by sweeping across the still-wet surface with a soft brush to eliminate the lines once rolling is complete.

Create stop ends when laying larger areas

Use a board or similar to create a straight-line edge when the whole of an area cannot be covered in one shift. Don’t ‘feather out’ the aggregates and rely on a tapering overlay but treat the surfacing as a macadam or concrete surface with a neat, well-formed and straight stop end.

The subsequent shift can remove the stop end and commence laying against that edge. Once the surfacing has been wet-rolled, the ‘Day Joint’ between the two areas should easily disappear when worked over with a soft brush.

Protect the newly completed surface.

The newly installed surface needs some time to dry out, harden and become ready for use by its intended traffic.

The actual time needed depends on the weather. It will dry out much more quickly in the dry, warmer days of summer, maybe needing a week or so, whereas in the damper, cooler days it could need two weeks.

During this time, it’s best to keep all traffic, foot and vehicular, off the surface to prevent scuffing, rutting or marking.

Availability:

Breedon Special Aggregates offer customers a FREE sample service.

Request samples of up to TWO aggregates for free delivery to enable a better appreciation in natural daylight to see how they complement the site and the surrounding buildings.

Use the contact information below to request samples...

Breedon self-binding gravels and all other decorative aggregates in the Breedon Special Aggregates range are available nationwide:

Breedon run a nationwide flet of distinctive Hiab crane-offload vehicles, 4 wheel rigid tippers, 8 wheel rigid tippers, and articulated tippers.

- Buy Direct from the Quarry

- As loose loads (by wagon)

- In 800kg bulk bags

- Buy Online via the UK Stone Direct Website

- Order via a local Builders’, Civils, and Landscapers’ Merchants

- Some Landscape Merchants stock loose material

Video:

Breedon Golden Amber Gravel from Breedon Special Aggregates on Vimeo.

Aftercare:

As the completed surface is used, small, loose chippings may appear on the surface. This is not in any way detrimental to the surfacing, but, if a clean and chipping-free surface is preferred, they can be swept away.

No matter what form of paving and surfacing has been used, there is no such thing as a maintenance-free product, and so a little basic care and attention is needed to keep the self-bound surface in tip-top condition.

Weeds can be kept at bay by regular application of a good quality weedkiller to the less-frequently trafficked areas.

Potholes should be repaired as soon as possible – these things never, ever get any smaller, so the sooner they are fixed, the less of a problem they will be. Cut out the damaged area allowing at least 100mm spread beyond the extent of the pothole and remove all of the self-binding aggregate to expose the sub-base beneath. Fill the prepared ‘hole’ with fresh self-binding aggregate and compact exactly as described above. For smaller potholes, a vibrating plate compactor could be used if a roller is not available or unsuitable.

In autumn and winter, remove any accumulation of leaves or other garden litter. It doesn’t cause significant structural damage to the surface but some leaves with a high tannin content can temporarily discolour the surface.

Gallery:

Breedon Self-Binding Gravels

Other Decorative Aggregates:

Breedon Special Aggregates supply an extensive range of decorative and construction aggregates. All these aggregates, and many more, are available direct from the quarry or via the UK Stone Direct Website

Downloads:

Further Info:

Breedon Special Aggregates

Pinnacle House

Main Street

Breedon On The Hill

Derby

DE73 8AP

Tel: 01332 694 001