Civils 2005 - a review

Tuesday, Wednesday and Thursday of last week (November 22-24th 2005) saw the Civils 2005 show hit London Village. There had been much discussion in Upper Britain regarding the show's relocation to the lower right hand corner of these islands, and the prevailing attitude among many Northern and Scottish Civil Engineers and contractors was that London is too inconvenient, that it means an overnight stay or a couple of days out of the office, and this sense of inaccessibility wasn't helped by the frankly extortionate parking charges (6 quid per hour!!!) and a problem with those tinny tube trains on the Tuesday that reduced service up to Olympia to a pathetic once every 30 minutes.

So: having successfully found the funding to cover a couple of days in London by raiding the kids' piggy banks, and having managed to find the way to this Olympia place, what was there that might be of interest to us in the paving and drainage trades? Although paving and drainage are essential parts of the civils industry, it tends to be the "specification" products and contractors that identify with civil engineering while most of the patio and driveway products/contractors feel more at home in the 'landscaping' category. Accordingly, there was never going to be any chance of seeing, say, wet-cast patio flags or rope-top edgings. However, it would be reasonable to expect commercial paving products, pedestrian and car park drainage items, and the occasional bit of kit intended to make our lives easier.

An initial 'reccy' of the cavernous National Hall revealed just one paving manufacturer promoting paving, a handful of drainage manufacturers, and one paving kit and materials handling supplier. Lots and lots of 'service providers', such as insurers, mapping companies, project managers and others who never get their mitts dirty, and a good selection of geo-tech companies, ranging from surveyors through soil stabilisation to ground anchors and more. There was also a healthy offering of survey kit - theodolites, earth stations, laser levels, etc. - and a good turnout from some of the big international names in the civils design and management sector, including Atkins (of course!), the legendary Murphy group, Faber Maunsell, Mouchel, amongst others. But where were the products? LaFarge, Cemex (what used to be RMC), Tarmac and Charcon all had a subdued presence, but no sign of industry behemoth, Marshalls, no Hepworth, no Polypipe, no McAlpines, no Terram .... in fact, it was quite interesting to note just who wasn't there. If this is to be a national event with any credibility, it has to be supported by those companies that are happy enough taking millions of quid out of the industry each year.

Formpave

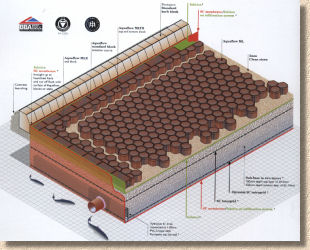

In view of all that, those companies that did turn up deserve a round of applause for making the effort. As this website is dedicated to paving, the only paving manufacturer actually promoting paving at the show warrants first mention, so stand up Formpave and take a bow. Well done for representing the rest of the trade, and for putting on a display to show off the best of British segmental paving along with a genuine British stone, the gorgeous Forest of Dean sandstone. The 'standard' paving products were well received, but it was the permeable paving system, Aquaflow, that attracted most attention, and rightly so.

SUDS is the buzzword for much of the groundworks trade at the moment, and permeable paving is an integral part of this new approach to draining our towns and cities. Several years ago, Formpave committed themselves to what was then an unfashionable idea, but they could read the runes better than many others, and now that SUDS is the zeitgeist, they have established themselves an advantageous lead over their competitors and simultaneously enhanced their reputation with their generous support and funding for some of the cutting-edge reserach being undertaken at several universities.

Permeable paving systems are just the sort of product that should be showcased at an event such as this. Now, when the next generation of designers are asked to suggest a suitable permeable system, it's more likely that the name Formpave will be at the forefront of their thinking: and rightly so!

Incidentally, watch out for a review of the new Formpave Specifier's handbook on next week's news page, which, if all goes to plan, will be uploaded on Sunday, December 4th 2005

Probst

From paving, it's a logical step to consider next the paving kit, those tools and machines that make the installation and maintenance of paving that much easier.

As mentioned in last week's news item , Probst have unveiled a ickle baby block splitter that weighs a bit less than a navvy's butty and can happily chomp its way through blocks up to 100mm thick. I had my first close up look at the new machine, and it is as you'd expect - wonderfully well engineered, and simple to operate. Paul Bolland, head honcho at Probst's UK distributor, reckons this midget gem should retail around the 250 quid mark, but it's not certain that it will be made widely available just yet. It's being shown to various contractors for feedback, and the main concern just now is the width which precludes longitudinal cuts and cutting certain tumbled blocks.

Also on show were the superb pavement power washer and lifting kit both mechanical and vacuum, ranging from the deceptively simple yet powerful VPH Vacuum Power Handy to the trailer-mounted BV Jumbo. As the manual handling regulations start to be enforced (allegedly!) these pieces of kit will become an essential for anyone involved in laying road kerb or the larger flags.

And speaking of the road kerbs, one noticeable trend addressed by at least three other exhibitors is the need for a lightweight kerb.

Durakerb

Durakerb were featured on a news page back in June and it certainly attracted a lot of attention. A 6kg HB2 road kerb? Too good to be true, surely, but Phil Sutton and the team at Durakerb managed it and it's been pretty well received by several local authorities and numerous contractors. Phil is pursuing BBA certification but it's not been as straightforward as he'd hoped, mainly because of the difficulties in testing what is a radical new idea to compare it with its concrete counterparts.The route to market for Durakerb has been re-assessed and they've now decided to sell via national civils distributor, UGS: indeed, Durakerb was just one of several interesting items on the UGS display, more of which later . For the new year, Durakerb are looking to launch a transition version (a dropper kerb to you!) along with a bull-nosed centre stone that will enable them to challenge for the retro-fitted drop crossings work that are a regular task for many local authority highway's teams.

Envirokerb

Just across from UGS and Durakerb, Envirokerb had a very impressive display of their range of kerbs and combined kerb-drains. These are manufactured from recycled materials and come in 'half kerb' sizes, ie; 457mm lengths, to comply with weight limits for manual handling. This was the first time I'd seen the Envirokerb 'in the flesh' and I was pleasantly surprised. It has a look of a dense, vibrated concrete, and an authentic texture. It feels solid, which is as it should be at 16kg per unit. It's not as light as the Durakerb, and at 22 quid or thereabouts for each kerb length (915mm or 2 units) it's around twice the price, but it does have the advantage of offering a wider range of formats, including Bus Stop Kerbs.

Aco

The combined kerb-drain units come in a variety of depths, to accommodate various flow quantities, and also in the full range of formats: HB2, transitions, centre stones, internal and external radius. The sales director told me that he's hoping to have a splay profile available next year but I'm banned from revealing any more than that. Meanwhile, over at one of the industry giants that did make the effort to put on a show, a different approach to the 'heavy kerb' problem. Rather than manufacture using plastics or reducing kerb length by half, Aco have stuck with their incredibly successful polymer concrete but have completely redesigned the kerb itself, reducing its top width to just 50mm, cutting down the height to 200mm and creating four full-width ovoid holes, all of which has reduced the weight of a HB2 profile kerb to just 16kg. As an ex-kerber (and I have the very knackered spine to prove it!) I found it hard accustom my eye to the slimline look of these kerbs, but as was pointed out to me, there's no good reason for kerbs to be 125mm or even 150mm wide - it's just a hangover from the days when kerbs were hewn from stone. It's the concrete haunch that provides the real strength of a kerbline: the kerbs themselves are often little more than a decorative face to the haunching. The styling of these lightweight kerbs ensures they will be well and truly locked in to the bed and haunch, and the trials to date have been very successful.

So: same problem and three different approaches to solving it. And there are maybe a dozen other approaches out there on the market, so perhaps it's something that needs covering in more detail on the website. For now, though, Aco have sponsored a basic website looking at the issues involved in kerb laying in the light of the MHRs. Have a look at kerblaying.com for more info.

Aco are probably best known for their drainage systems, particularly the channel drains which have become known in the trade as 'Aco Drains' even when they're not made by Aco. Consequently, a large part of their impressive, centrally located stand was given over to the drainage products, which can be loosely grouped into three classes: channel drains, combined kerb-drains, and slot drains. News from the channels drains is that there's a move to units featuring integral gratings, that is, the grating and the channel are one, composite unit. This helps deal with the problem of missing gratings, or inappropriate gratings being fitted, but it does mean that maintenance access is restricted and can only be achieved via dedicated access units that are placed every 20 metres or so. However, on the plus side, access via just two points (one in - one out) does mean that the supermarket car park doesn't need to be closed off during cleaning - the work carries on without disturbing the shoppers and other users, which should please the retailers. Training manager, Joe Bordas, is working hard on a handy 'pocket guide' that will help simplify selection of the most appropriate drainage product for specific applications, and I was treated to a sneak preview - look out for that at your local Aco stockist in the New Year.

In the combined kerb-drains, there's nothing radically new, just a wide range of capacities, and systems suitable for any project from a small cul-de-sac up to motorways and airport runways. However, in the slot drain section, the enormous Q-max system is attracting a lot of attention because it is amazingly discreet yet capable of carrying the sort of surface water volumes that had Noah offering the chippies an 'early finish' bonus. Q-max brings a number of advantages to the pavement structure, but perhaps the most unexpected ancillary benefit is that the trench prepared for Q-max installation is proving to be a remarkably convenient route for ducting, cabling and associated small-bore pipework. There's plenty of smaller capacity slot drains available, suitable for anything from a small patio up to a pedestrian plaza, and all featuring the heel-guard 'slot'.

Gatic

Also offering slot-drains, Gatic had a display of their various capacity products, but their Paveslot product features a plain-ended 10mm wide throat rather than the 'folded over' heelguard design favoured by Aco. Paveslot is specifically targetted at areas of block paving or flagstones, while larger areas can be drained using the UniSlot system and for heavy duty applications, the UltraSlot is the preferred option.

It's difficult to say that such-and-such a slot drain is "better" than another: they all function; they all meet the standards; so how can 'better' be defined? It has to be something to do with ease of installation, range of fittings and accessories, and the service provided by the manufacturer to both designers and installers. In that respect, the design software provided by Gatic is truly wondrous.

Being a man of impeccable taste, Gatic's marketing manager, Mark Stanway, also lives on the outskirts of the thriving metropolis of Warrington, and so, in a little under 5 minutes, we were able to re-design the stormwater system for the centre of town using the Gatic software and some basic information regarding street lengths, widths and gradients. In next to no time, the whole of Bridge Street, Buttermarket Street and Sankey Street had all their drainage problems resolved. What impressed me most was the facility to 'add on' side branch runs of slot drain and the software would automagically re-spec the main run, upgrading the channel size as necessary to cope with additional flow....and all at the click of a mouse!

Pipex

Sticking with drainage for a while longer, the one manufacturer to put in an appearance was Tiverton's Pipex , manufacturer extraordinaire of composite manhole chambers. These are one of those products that are difficult to understand until you've seen them, and when you have, you'll never want to risk life and limb messing about with concrete chamber sections again.

The manholes are manufactured to order, so the inlet and outlets can be arranged at the precise angles to eliminate any need for open channel pipes and awkward benching. Even the steps are built into the side walls, so all that is required to install a manhole is a fresh concrete base on which to bed the pre-formed composite chamber, and once it's aligned and levelled up, a wet mix concrete is poured into the void between inner and outer chamber walls, vibrated into place and left to cure. No need to wait 7 days before striking shuttering, no precarious balancing of concrete rings on bits of brick and flagstone, and what's most surprising is the price - these are very, very competitively priced, enough to make you wonder just how much longer there is for the traditional concrete sectional chamber.

Eccles UK Foundries

While Pipex might like to think the days of the traditional concrete chamber may be numbered, Eccles UK Foundries aren't overly worried whether the manhole covers are the traditional ductile iron, steel or one of the new composite materials, because they produce them all! What attracted my beady eye, though, was an array of composite recess trays. "Composite" is the new wonder material in manhole covers. Over recent years, the price has come down sufficiently for it to be used in the sort of applications traditionally reserved for heavier materials. It's incredibly strong and versatile, and for something has heavy and cumbersome as a manhole cover, it makes a viable alternative. For recess trays, though, the advantages may be less apparent - 4mm galvanised steel isn't all that heavy in the first place, so what else can a composite material offer? Well, a longer lifespan for a start. Eccles boast of a 50 year lifespan for their composite covers, compared to 25 years for galvanised steel.

The trays come in four basic plan sizes (300x300mm - 450x450mm - 450x600mm - 600x600mm) and in depths to suit 50/60mm pavers. They're rated as being capable of supporting a 3.5 Tonne load, and feature four, screw-fasteners, each with a heel-guard cover for those contractors eager not to damage their stilettos.

Business Development Manager, Nicola Bird, tells me that she normally sells via Civils and Builders' Merchants, but is not averse to selling direct to contractors, as long as they buy in multiples of twenty.

Instarmac

And to bed your manhole covers, why not consider Instarmac's resin-based bedding material for ironwork. It's simply mixed with sand to create a very fast setting mortar to facilitate bedding of manhole covers, gully tops and the like when getting the road open to traffic once again is a priority. Combined with other fast-setting products from the Instarmac range, such as the Ultracrete Rapid Set concrete and the Ultracrete Instant Road Repair macadam, reinstatements can be opened to traffic in just a couple of hours.

Instarmac were also staging live demos of the bedding and jointing products for setts, a demo that always goes down well. In under an hour, the Cembuild HS bedding and Ultracrete Flowpoint jointing have set as hard as nails and provided a completely filled, full-depth joint, which is essential for setts. Although the Flowpoint is aimed primarily at Highways work, there's a growing demand from contractors laying setts to private driveways and patios, looking for a simple and clean jointing option.

Nufins

Another company offering sett bedding and jointing products are Universal Sealants - Nufins . They provide two simple options - the Nucem HB Bedding Mortar and Nucem Joint Grout, or the all-in-one Hispec Paving system that can be used for both bedding and jointing of stone paving, setts and cubes on both pedestrian and vehicular areas.

Nufins also offer a range of quality paving sealants, including BlockSeal which has been specially formulated for concrete block paving, acting both as a sealant to protect the surface and reduce the incidence of weed growth, and as a sand binder, fixing the essential jointing sand and resisting scour. They've also recently launched Covergard, a fluorochemical sealant developed to be used wth a wider range of surfaces, both horizontal and vertical. Watch out for more information regarding the Covergard product in the next few weeks.

Not content with providing high strength bedding and jointing products, along with impressive sealants, Nufins also offer a resin bond surfacing system, StoneBond. Despite the name, this is a resin bound system (ie, it's trowel applied) targetted at civil and commercial projects.

Stirling Lloyd

Just a few metres away, Knutsford's very own Stirling Lloyd also offer a resin-bound system (see the Resin Paving pages for an explanation of the difference between resin-bonded and resin bound surfaces) which I saw for the first time and was strangely drawn to a sliver-grey granite version as an attractive alternative to the more usual bauxite. It's not S-L's core product line, but their position in the structural and civils industry should enable them to gain market share in this rapidly expanding sector of the surfacing market. Stirling Lloyd also supply the Pardak roof paving support system that is used in conjunction with the Dreen paving slabs manufactured by Zoontjens in Holland. S-L's interest is in providing the underlying waterproofing membrane, Integritank.

A quick review of the subdued efforts from four of the biggest names in the civils and building materials sector: Cemex, Charcon, Tarmac and LaFarge. OK; so Cemex may not be a household name, but that's only because they've hardly banged the drum about their purchase of what was RMC, one of the best known brands in the industry, but the other three should need no introduction. So why such a subdued, understated presence? Was this a toe-dipping exercise? Were they unsure of the show's focus, or unsure of what they could offer?

Cemex

For Cemex , there was a sense of re-introducing themselves to their market, reminding folk that they've not gone away, but have been having a bit of a think about who they are and what they can provide. Their stand featured more Cemexians in pale blue branded shirts than actual products, although they did have a handful or cores from various macadams and asphalts. Nick Longford was pushed forward to answer questions regarding the RMC paving range, and freely admitted that the brand has been in suspended animation since being bought out by the Mexicans last spring. There's no new Cemex publicity material - they're still sending out the old RMC brochures - and it will be next year before they get around to reviewing the paving range and deciding what to do, when, where, and why. Until then, just keep referring to the familiar Readypave products.LaFarge

Strangely, LaFarge had a similar approach. A non-entity of a stand who's most noticeable feature was competition to guess the number of stones in a sweet jar partially-filled with 10mm aggregate. Since selling the old Redland CBP plant to Brett a couple of year's back, LaFarge have no presence in the direct manufacture of concrete paving other than their Bomanite PIC brand, but they retain an interest in aggregates and surfacing. I found it hard to summon up any interest in this offering.Tarmac CMS Pozament

Tarmac had tucked themselves away at one edge of the proceedings and although they were willing to talk about the group's wider remit, they were primarily promoting the highway maintenance products sold under the CMS Pozament brand. Three products in particular caught my eye: RoadMaster SMA used for permanent cold-lay reinstatements on carriageways; PathMaster, a HAUC approved cold-lay reinstatement macadam for footways and cycle tracks; and RepairMaster, a cold asphalt material for repairs to almost any pavement surface.Charcon

Last but not least of the big four comes Charcon, who used the show to promote the Special Products division which normally focuses on pre-cast concrete ducting and cabling protection systems for various industries, most notably the rail networks. Given Charcon's eminent position within the civils products market, one might reasonably have expected to see more of their extensive hard-landscaping range, but as with the other 'majors', they seemed keen to push one of their lesser known imprints to the fore.

However, they had managed to dedicate one corner of the display to the permeable paving system that relies on the award-winning Permavoid SUDS system and Infilta concrete block paving. Regular readers of this website will know that I've been banging on about SUDS for years and although Charcon weren't the only manufacturer to exhibit a SUDS paving system (see Formpave above) they deserve a round of applause for putting it at the front of their otherwise unrelated display.

Grace Construction Products

A quick final mention for a handful of other exhibitors that had products of interest: Grace Construction Products , another company located in Warrington, specialise in admixtures and treatments for concretes. If you've been in the industry for any length of time, it's quite probable that you've used or benefited from Grace products without even realising. Stonemarket flags? They use Grace additives. Marshalls? So do they!

However, despite the excellent products, what seemed to be attracting most attention were the cuddly green frogs being given away. Not wanting to sound sexist in any way, but it did seem that every woman visiting the show had made sure they got their hands on their very own cuddly green frog, and most had been given a name within seconds!

Hoofmark

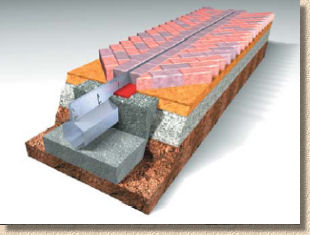

Hoofmark had a busy stand showing off various products, including the Golpla grass reinforcement systems, the superb D-raintank storm crate, and the D-rainclean stormwater control system (more SUDS products), but they did seem to be interested only in talking about the new Deltalok retainer system that was likened to a "green gabion". I made several attempts to talk to someone, anyone, on the Hoofmark stand over the two days I was there, but never succeeded in being able to converse with anyone about anything other than the Deltalok, which is, in itself, a worthy product, but not what interested me, primarily.

UGS

More luck on the stand put together by specialist civils merchant UGS which had been given over to a selection of innovative civils products, including the Durakerb discussed earlier. One other item that really caught my eye was a modular access chamber kit that facilitates extremely fast construction of access chambers in general and BT chambers in particular. It's another of those ideas that is blindingly obvious once you've seen it - almost like a big Lego kit, and, from what I was told, is extremely competitively priced. The units are manufactured in Belfast by Salmor and promoted via UGS by a Wigan-based company. If access chambers are your thing, you must take a look at this cracking innovation - if you don't, your competitors will!

Parker

And to finish off, a mention for Parkers , one of the longer established and best respected supplier of contractors' tools, roadworks kit and PPE. Other than the ultra-expensive high-tech surveying kit, there wasn't much in the way of everyday 'tools of the trade', and I felt is was a good thing to be reminded how those at the dirty end of the civil engineering industry still earn their pay - with picks, shovels and wheelbarrows.

Overall, it was probably worth a two-day trek to London, but with so many firms from the big city of Warrington or other northern and midland locations, it did make me wonder, yet again, just why where we conned into traipsing all the way down there? The 2006 civils event is already booked in for the same venue (November 28-30th 2006) and it seems that the South-east massive have decided to ignore the fact that there are more civil engineers, civil engineering contractors, and civil engineering universities outside the goldfish bowl of London than there are stuck inside that gridlocked, dirty, overpriced hellhole. If this is to be a "national" event, let's make it easy for the WHOLE nation to attend, and not just those in one corner.