Introduction:

Grass Paving can be utilised in those areas where the hard permanence of a typical pavement might be undesirable, such as in conservation areas, roadside verges, emergency services access, canal towpaths, farm tracks or rural settings, and they are also used for erosion control in some situations, although the specification and type of system(s) used can be completely different to that outlined below.

Different proprietary systems provide varying ratios of hard-pavement to grass, and the best system for any given project will need to take into account these differences. Some systems can only be installed by specialist contractors, while others can be installed by competent workmen or even diy-ers. It should also be noted that special grasses ought to be selected for planting the various systems, as most ordinary seed mixtures are unlikely to be sufficiently hard-wearing to withstand being trafficked. A few suggested seed mixtures are given further down the page.

The 5 techniques considered on this page are:-

All these techniques rely on a sub-base to give the paving its strength, although the types of sub-base recommended will vary with type of system chosen, existing ground conditions, and anticipated usage. A typical construction detail for each technique is given below.

{adsense-grass}

Hopsack Paving

This is the simplest of the 4 techniques, and utilises readily-available, plain rectangular concrete paviors, laid to a pattern that leaves significant 'holes' or 'pockets' that are filled with soil and seeded.

This technique can be used for residential driveways, or in the garden. For path use in a garden with reasonably firm and stable soils, the sub-base can be omitted, but be prepared for the bricks to move.

Any rectangular blocks can be used to create a hop-sack pattern resulting in varying sizes of 'pockets' in the finished pavement. The edges of a hopsack pavement sill need to be solid, either against an existing sound structure, such as a wall, or with an edging unit or soldier course laid on concrete, as described on the Block Paving Page.

For residential driveways, patios and paths, a 100mm sub-base is usually sufficient (see Sub-base Page), but heavier loads, such as large vans, may need 150mm thickness. For trackways, car-parking areas etc., consult a paving contractor or civil engineer for specific advice.

Once the blocks have been laid, the pockets should be filled with a well-draining, friable soil, or soil/sand loam, and compacted as for normal block paving. It's worth spending a few quid, if necessary, to get a decent planting medium, as the grasses will have only this small pocket of soil to survive upon for the next few years. The soil in the pockets can be seeded immediately with the selected grass mixture, although the soil will settle over the ensuing weeks and may need 'topping-up', or it can be left to settle for 4-6 weeks and topped-up prior to seeding.

The relatively small proportion of grass to each square metre of this type of grass paving make it less reliable than other techniques, and there is a tendency for the grass to die off within a couple of seasons, but it does have its uses, and, if fed with a liquid fertiliser and watered in dry weather, it can look quite attractive in the right situation.

{adsense-grass}

Spaced Paving

This technique again relies on commonly available block paviors, that are laid on a prepared sub-base and bedding layer, with 'spacers' between adjacent blocks giving a wide, but consistent, joint, that is then filled with the selected soil prior to seeding. Different manufacturers have different proprietary systems, but they all utilise a square or rectangular 'standard' block with some form of spacer, often plastic, approximately 30-45mm wide. The number of spacers per block is determined by intended usage (more spacers used on trafficked areas) and type of block. Full instructions will be supplied by the spacer/block manufacturers.

Again, this technique can be used for driveways, paths, patios, and, with a more substantial sub-base, for trackways, car parks and other large-scale, low traffic-speed sites.

The choice of block, and the width of the joints, determine the ratio of grass:hard-paving, and this allows this ratio to be manipulated, by choosing larger or smaller blocks, to suit individual site requirements.

For example, using 240x160mm blocks with 35mm joints results in approx 29% grass by area, whereas using 160x160mm blocks, this ratio becomes 33% grass joint by area.

Again, soil and seed need to be carefully selected, before filling the joints, and the grass should be allowed to establish itself before allowing vehicular traffic to use the pavement.

Grass does seem to survive better in the joints of spaced paving than it does in the small 'pockets' of hopsack paving, and, along with feeding and watering in dry spells, it may even need the occasional attention of a mower.

{adsense-grass}

Cellular Paving

See also Cellular Systems Page

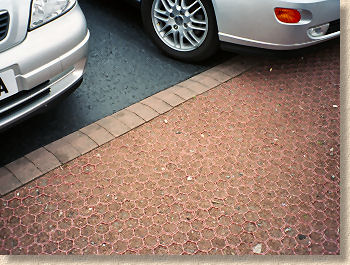

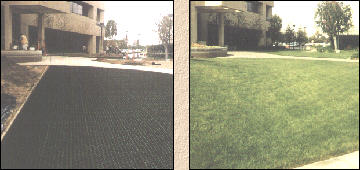

This is the most widely used type of grass-paving, and is claimed to be structurally sounder and stronger than other forms. Basically, specially-shaped, interlocking 'cell' pavers are laid on a prepared bedding layer over a sub-base, and the 'cells' filled with the chosen soil and seed. There are a good number of proprietary systems available, in 3 formats; pre-cast concrete cells, plastic cells, and cast in-situ concrete cells.

Different proprietary systems have differing bedding layer requirements, and you will need to check with manufacturers whether their system requires a granular, a grit sand, or a sand/soil bedding layer.

Generally speaking, these pre-cast concrete units are laid using the same methods as outlined on the block paving page.

This technique is suitable for all but the very heaviest applications. The scale of the project, and its intended use, will determine the best system to be used. Some manufacturers are not equipped to cope with orders of less than 300m², although it may be possible to arrange for a local builders' merchant to obtain a smaller quantity. These systems are quite popular with local authorities looking to provide hard-standing or emergency access to otherwise 'green areas', such as pumping stations on residential estates, and access trackways for service vehicles, fire engines, etc..

Grasscrete ® is a proprietary system that relies on placing disposable plastic 'pots' at equal spaces over a prepared base and then pouring concrete to fill the spaces in between the 'pots', which act as temporary formers for the eventual pavement. Once the concrete has hardened, the flimsy plastic pots can be removed, and a selected soil mix used to fill the resulting voids. The soil can then be seeded.

Some systems allow gravel, decorative aggregates or bark to be used to fill the cells in place of the more usual grass, and some manufacturers will supply cells ready-turfed if required. Filled with a gravel, these plastic cells can bring stability to an inclined access way, and help minimise the inevitable drift of the gravel to the bottom of the slope. Plastic cell matrices (as they are sometimes known) are considered in more detail on a separate page .

The type of system chosen dictates the grass:hard-paving ratio, with some thin-walled plastic cells, offering up to 94% grass surface, rendering the structural elements virtually invisible, while others, such as the pre-cast concrete units that are available, make a feature of the cell shape, which is usually rectangular or hexagonal.

All of these cellular systems have been specially developed to ensure that the grass can and does survive, so much so that they can sometimes become overgrown if not tended regularly. Indeed, some systems are so successful at nurturing a natural overgrowth that they have been used on SSSI and sensitive heritage projects.

{adsense-grass}

{adsense-grass}

A comprehensive case study following the installation of Ground Reinforcing Grid System plastic cellular pavers to a multi-vehicle parking area can be found on a separate page by following this link

The grass jointing is essential to the structural integrity of such systems. Where grass growth is absent or poor, the individual blocks have a lowered resistance to differential movement when trafficked. In regularly trafficked situations, this can result in sub-base pumping via the gaps between the individual units. Firm edge restraint is essential as any rooting through to the sub-base will be tenuous at best and the units will spread under load.

Castellated or studded systems can be difficult for pedestrians as the soil fill within the units settles under vibration or is washed from the surface, leaving a protruding 'stud' which presents a significant trip hazard.

Only really suitable for low-speed occasional use. The relatively thin depth of these systems and their inherent flexibility can result in 'trampolining', where the units 'bounce' when trafficked. This can turn the surface into a quagmire in regularly trafficked areas, such as car-parks. The trade-off for a higher ratio of grass cover is a reduction in tolerance to wear and loading. Should not be used on gradients where slip resistance is essential.

Each job can be individually designed according to traditional slab design methods to ensure competence and adequate drainage control. No differential settlement or lateral spread, so no need for edge restraint. The only system suitable for vehicular loads of 40 tonnes.

Gravel fill is acceptable in low-traffic situations, but hoggin should never be used as it will 'set' and kill off any grass.

Where reinforced grass paving is used for Fire Path access, special note should be given to the sub-base, which can quickly become saturated.

{adsense-grass}

Reinforced Turf

This is a comparatively new development and, as far as I can ascertain, there have been only a few case studies of this type of technique, but it does have its admirers, and there will most probably be a small, but steady, market for it. The basic principal is that a specially selected grass is grown on a geo-membrane, which is then laid over a prepared bedding layer and sub-base. The sub-base provides the strength and stability, while the geo-membrane holds the grass layer together.

Manufacturers claim that this type of system can be used for most normal, low traffic-speed applications, although whether it will ever be developed and promoted to the sports industry or the general public remains to be seen. This system ensures 100% grass coverage, and the usual maintenance, such as feeding and mowing, will need to be undertaken on a regular basis. The life-time of this system is an unknown quantity at the time of writing, but should be good for 10 years.

There are also reinforced turfs developed specifically for erosion control, rather than trafficking, and are beyond the remit of this site. However, Some of the manufacturers listed on the links page also supply these 'erosion control mats', and their technical departments will be more than happy to help you with your queries.

{adsense-grass}

Mesh Protected Turf

This system is becoming quite popular with those responsible for overspill car-parking and pedestrian usage at occasional events, with groundsmen looking after areas of lawn, and with caravan/leisure parks, where the natural appearance of grass with the load-carrying ability of a pavement, all at a minimal cost and with little or no construction work required, is very appealing.

The basic premise is that a tough polypropylene or HDPE mesh is laid over an area of turf or grass, and this allows foot-traffic, low-speed cars and vans to use the area without completely ruining the grass. The mesh may need to be anchored to the ground at regular intervals by means of ground pegs, to prevent slippage and to help disperse the loads. The mesh works to protect the grass roots from being damage, to minimise ' pumping ' of wet ground, and to avoid rutting of soft spots.

The soil type, the type of grass/turf cover and the level of protection required will determine the best mesh to choose for each application, and the better manufacturers have dedicated technical teams to help in identifying the best solution.

For lawned areas, the mesh is simply rolled out over the close-cropped turf, with adjacent rolls overlapping by 150-300mm, and anchored with ground pegs. Any dips, hollows, soft-spots etc, should be levelled out with grit sand or top soil before placing the mesh. Once laid, they can be left in-situ for the season, or even permanently, as most commercial mowers will ride over the embedded mesh without hindrance. For areas with longer grass, the meshes are placed after a mowing, and the grass is allowed to grow up and through the mesh, hiding it from view, yet providing sufficient stability to permit trafficking.

{adsense-grass}

Grass mixtures

All to be applied at approximately 20-30 g per m²

General Parking

- 50% Perennial Ryegrass

- 20% Slender Creeping Red Fescue

- 25% Strong Creeping Red Fescue

- 5% Browntop Bent

Driveways

- 80% Chewings Fescue

- 20% Browntop Bent

Verges and Picnic areas

- 35% Smooth Stalked Meadow Grass

- 30% Slender Creeping Red Fescue

- 25% Perennial Ryegrass

- 10% Browntop Bent

Accessways

- 30% Hard Fescue

- 20% Chewings Fescue

- 20% Slender Creeping Red Fescue

- 25% Strong Creeping Red Fescue

- 5% Browntop Bent

Other Ground Reinforcement pages ....

{adsense-grass}