This installation was observed and documented independently by pavingexpert.com from May to October of 2015.

The manifold benefits of using resin mortars to joint all sorts of pavements has been exhaustively covered on other pages in this series , but all the other products so far mentioned are intended for use with wide-ish joints, by which we mean joints wider than 6mm. However, as the range of materials used for paving has expanded exponentially over the years, so there has been a trend to using narrower and narrower joints, and once these joints drop below 6mm in width, the 'standard' resin mortars are not really suitable.

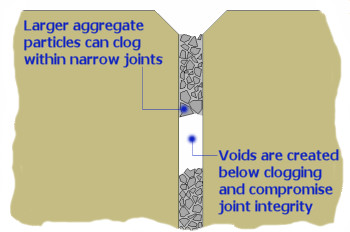

This is because the aggregate used is not really small enough to ensure that it can both enter the joint with ease and, more importantly, fill the joint completely without clogging which would result in voids within the jointing. Voids are a serious weakness within the joint and their presence makes it more likely that the jointing material will crack or fail and thereby threaten the structural integrity of the pavement.

Many of the more fashionable paving materials, such as sawn natural stone and, in particular, ceramic or porcelain paving , are manufactured with fairly exacting tolerances which enables them to be laid with what are referred to as close joints : joints that are in the range 2 – 5mm in width.

A fine mortar

To ensure a jointing material can enter the joint and fill it completely without clogging, a finer aggregate than usual is required, and to meet this new and growing demand, NCC Streetscape in conjunction with Germany's leading manufacturer GftK have used their extensive skill, flair and experience to produce a super-fine aggregate two-part resin mortar which is just about ideal for such applications. Somewhat less flair has been used in coming up with a catchy name for this product which struggles under the the burden of being known as VDW 815 Plus .

This new formulation has another advantage, as though being super-fine wasn't enough: it responds most favourably to being super-saturated with water during installation.

There is no such thing as too much water. It cannot be over-wetted.

In fact, the wetter the better. The paving to be jointed should be thoroughly soaked before putting out the mortar, and then more water can be used to help wash the mixed mortar into the empty joints. Finally, yet more water should be used to help wash off any surplus along with the residue once the joints are filled.

The use of plenty water has two major benefits when it comes to jointing pavements. Firstly, it ensures the resin-coated aggregates are thoroughly washed into the joints and compacted in-situ, with almost no chance of there being any partially filled joints or voids within the jointing.

Secondly, and most beneficial to porous stone pavings, by super-soaking the surface beforehand, the risk of the stone absorbing resin from the mortar is greatly reduced, and so the risk of the phenomenon known as picture framing, where a discolouration forms around the perimeter of each flagstone adjacent to the joints, is all but eliminated.

Installation Video:

The video below shows the basic installation technique. As with the other two-part rein mortars in the VDW range, the aggregate is pre-coated so only the bottle of hardener needs to be mixed in, and after approximately six minutes of thorough stirring, the now frothy mortar is emptied out onto the pre-wetted pavement surface and then guided into the empty joints using a brush or a squeegee, with more water being applied via a hose as required to keep the mortar moving.

Once the joints are filled and the mortar has had a few minutes to settle and lose its froth, more water and a soft brush are used to remove any surplus and to ensure any last bit of residue is removed.

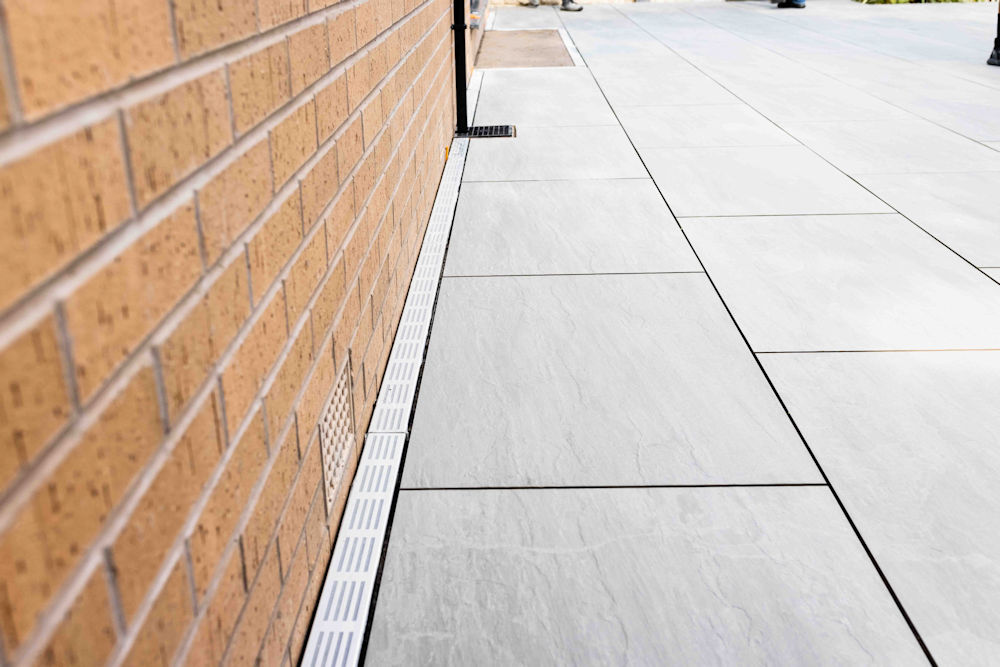

Residential Application - Merseyside Patio

The mortar will harden over the next 24 hours and can be opened to careful foot traffic after this period. Pavements used by motors are best given 2-3 days to harden more fully before being opened to vehicles.

VDW 815 Plus is available in three popular shades – sand, stone-grey and the dark basalt. These are very similar to other resin mortars from GftK but it's worth noting that, with a finer aggregate being used, the finished joint is noticeably smoother, less gritty, than those filled with the standard VDW mortars.

Case Studies:

VDW815 Southport

VDW815 Preston

Further Information:

Contact NCC Streetscape:

Tel: +44 (0) 1257 266 696

Other Product Studies featuring VDW mortars: