Terminology

There are three main types of joint: butt ; close ; and open .

This page makes a stab at trying to sort out just what is what, explain the reasons why we use one width of joint rather than another, and to dispel a couple of common misconceptions.

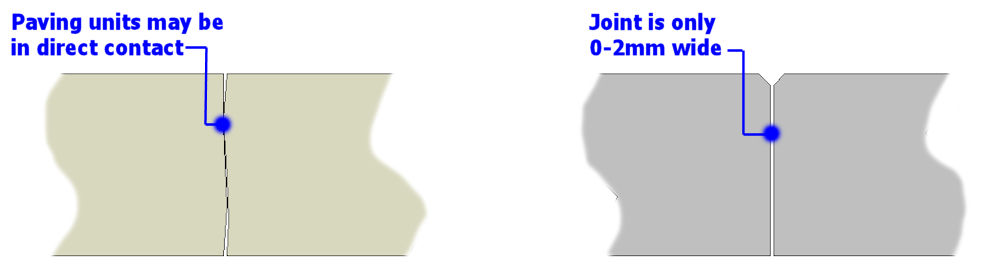

Butt jointing:

This is effectively no joint. The adjacent paving units are in direct contact with one another; they are 'butted' together.

Depending on the type of paving unit involved, there may be a very narrow strip of fresh air between the units, but to all intents and purposes, the gap between them is a minimal as possible and there will be numerous points of direct contact. Without resorting to some sort of sustained pressure system holding everything in place, it wouldn't be possible to have the joint any narrower.

Where it's used

- Cheap jobs such as shed bases

- Low traffic driveways

- Patios

Advantages

- No jointing medium required

- No additional labour required to carry out jointing

- No risk of staining from jointing medium

Disadvantages

Comments

- Very popular with cowboys who have no real understanding of pavement construction and eager to minimise the amount of effort they have to put in.

- May be justified on low-priority, low-traffic, low-budget jobs such as, for example, shed bases, bin stores and greenhouse paths.

- If it must be used, best used with chamfered units.

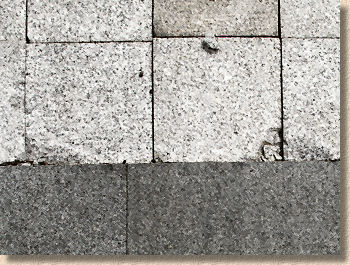

Gallery

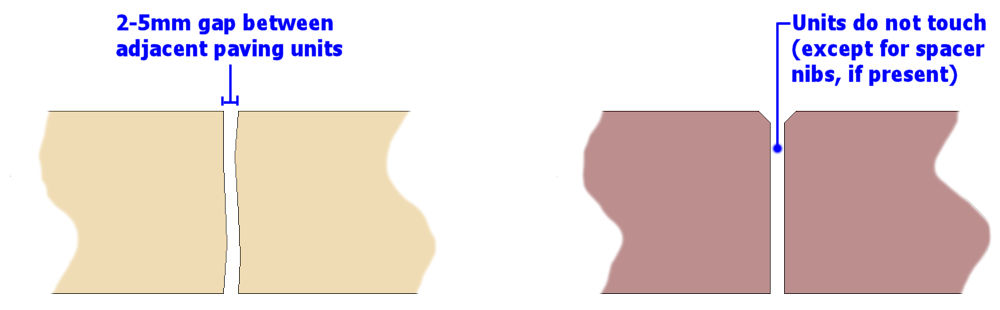

Close Jointing:

This is a narrow joint, usually 1-5mm in width. The adjacent paving units are close to each other but not actually touching at any point.

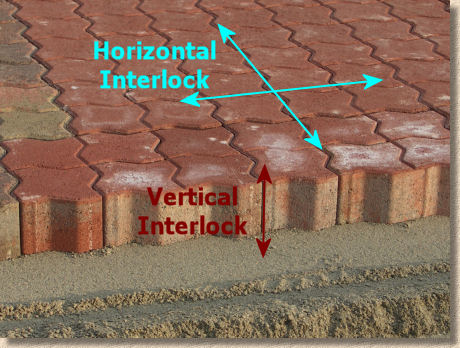

This arrangement allows a fine-grained jointing medium to fill the joint and create an essential cushion between the paving units and to generate a huge amount of both horizontal and vertical interlock which helps ensure the units remain firmly where they are meant to be.

Where it's used

- Most forms of concrete block paving , clay pavers , and permeable block paving

- High-quality sawn-edge natural stone sett and cube paving

- Small element concrete flags, sawn-edge natural stone flags , decorative patio flagstones

- Kerbs, channels and edgings

Advantages

- Relatively cheap

- Usually low-skill level required to install

- Helps prevent spalling

- Generates phenomenal horizontal and vertical interlock

- Enables easy maintenance and repair of pavements

- Usually clean to install with little risk of staining

- Useful at disguising minor dimensional variations of paving units

Disadvantages

- Unbound, loose jointing material prone to loss by scour from wind or water

- May be colonised by weeds

- Usually requires intermittent minor maintenance

Comments

- Should not be underestimated. Deceptively simple, but this is how pavements have been jointed for over five thousand years, right from the earliest mud brick roads of ancient Babylonia

- The key is to use the right sort of jointing medium : hard, angular grains are always the best option

- The few disadvantages are easily countered by using stabilisers , sealants and basic regular maintenance

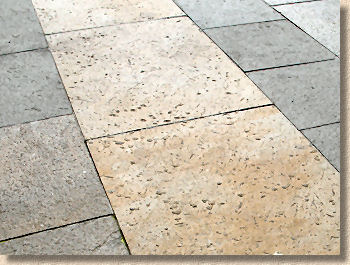

Gallery

Bloody good work!

Circa 2010 - is that progress?

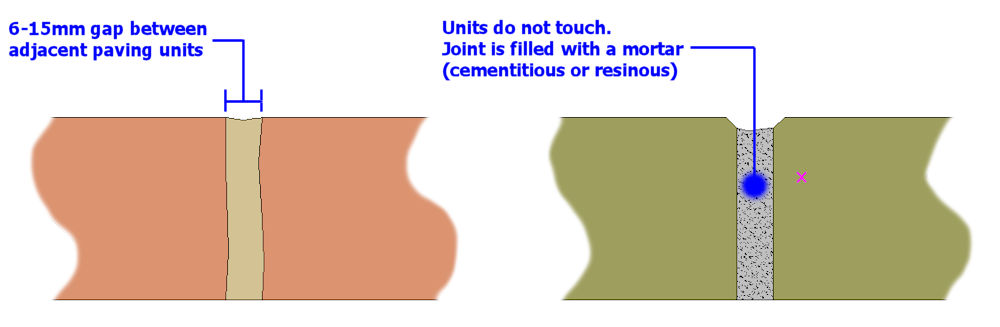

Open Joints:

Open joints are just what the name suggests: they are wide, gaping maws between the paving units and need to be filled with something substantial, usually a bound jointing medium such as a cement or resin mortar.

There has always been some debate over just what width is the boundary between close and open joints. It used to be a quarter inch (6mm) but some said three-eighths (9mm) which I always thought of as being too wide to be considered a close joint. Modern thinking seems to be settling at the 5mm mark, but there will always be some who want to see it pushed to 8mm or so.

For projects where a regular, consistent joint width is required, the use of paving spacers is often the best option.

Where it's used

- Traditionally with natural stone setts and cubes , as well as natural stone flags .

- With the advent of dimensionally accurate concrete flags in the interwar period, the tradition of open joints persisted (I spent most of my 1960s childhood filling the damned things!) and it's only with the emergence of small element paving in the late 1970s that its use with flags has reduced.

Advantages

- Holds paving firmly in position

- Almost no risk of spalling

- Can provide an attractive contrast to the paving units

Disadvantages

Comments

- Highly traditional but cement mortars nearly always crack

- New generation of proprietary cement mortars and resin mortars reduce incidence of cracking and allow high-pressure washing

- Slurries and gun-injected mortars are increasing in popularity

Gallery:

Other definitions:

Jointing Medium:

- The material used to fill a joint

- May be bound or unbound

- Cement mortars , resin mortars , sand , splitt , pitch , etc

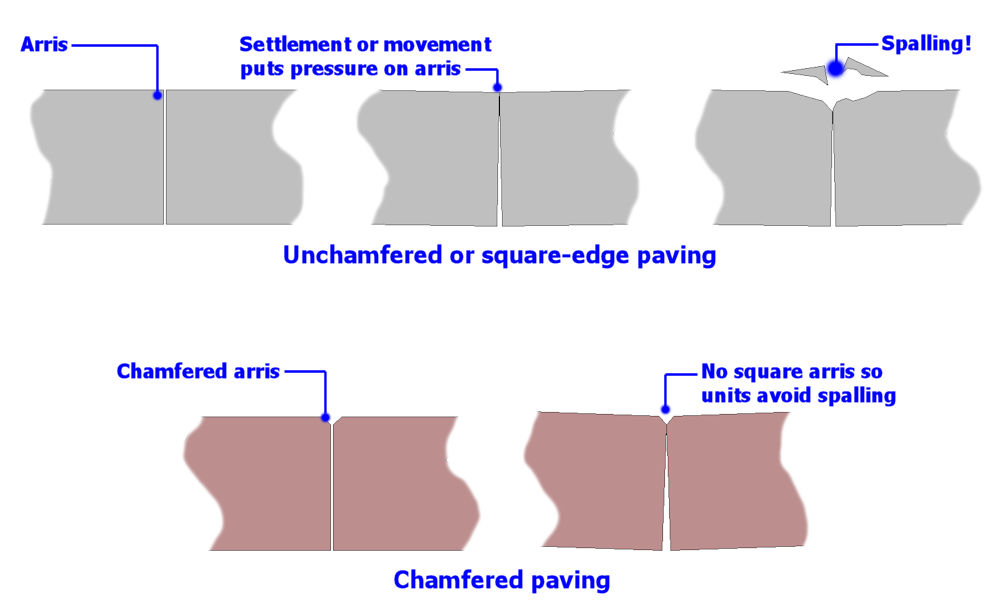

Spalling:

- Chipping or other damage to the edge or arris of a paving unit, often caused by the unit being in direct contact with an adjacent unit.

- Spalling can occur during installation, which we call "bad workmanship", or it can occur post installation due to there being no 'cushion' of jointing material between paving units, allowing them to exert pressure on neighbouring units

Horizontal interlock:

The friction generated by the jointing medium which helps the paving units resist forces which try to shift it in the horizontal plane, ie backwards, forwards, side-to-side, or rotationally.

Vertical interlock:

The friction generated by the jointing medium which helps the paving units resist forces which try to shift it in the vertical plane, ie, up or down.

Chamfered Units:

Paving units where the arris, the edge where the vertical sides face meets the horizontal base or top surface, has been modified to an angle of around 45°

This helps relieve pressure on the most vulnerable point of contact, and so reduce the risk of spalling.

Commonly found on clay and concrete block pavers, high quality decorative concrete flagstones and small element paving flags.

Other pointing and jointing pages...

- Introduction

- Terms & definitions

- Pointing Styles

- Spacers for Paving

- Cement Mortars

- - Hand Pointing

- - Pointing Riven Flagstones Using Coloured Mortar: A Case Study

- - Wet Grouting

- - Dry Grouting

- - Slurry Grouting

- - Gun Grouting

- - Poured Grouting

- Resin Mortars

- - Polymerics

- - GftK Polymerics: A Product Study - VDW 840+

- - Romex Polymeric Mortars: A Product Study

- - Jointex Polymeric Mortar: A Product Study

- - Slurries

- - GftK Slurry Mortars: A Product Study - VDW 800 Permeable

- - GftK Slurry Mortars: A Product Study - VDW 850

- Re-jointing paving

- Pitch Jointing

- Loose Fill Jointing

- - Stabilisation

- Alternative Jointing Materials