Introduction:

As the use of stone paving has blossomed over recent years, particularly due to the increased availability of imported flagstones and setts , so more and more contractors, developers and homeowners have considered protecting their investment by using a sealant. However, not all sealants are suitable, not all offer the same degree of protection, and they can have different finished appearances.

But even more importantly, it should be noted that sealing of stone paving is not essential, mandatory or necessarily recommended. There is an urban myth, heavily promoted by those with a financial interest in selling and applying sealants, that all new stone paving should be sealed. The technical term for this is Bollocks!

In some cases, sealants on stone do more harm than good, and if you want proof that stone doesn't need sealing, have a look at The Appian Way in Rome. So far, it's only managed to last around 2,300 years: imagine how good it could look if they *had* used a sealant!

If you must use a sealant, I recommend allowing the stone to weather for at least one year, so that it goes through a wet/cold winter and a dry/warm summer which should eliminate any residual efflorescence and expose any weaknesses, fractures or other failings within the pavement. Then, after a thorough cleaning followed by at least three bone dry, warm days in which the paving can thoroughly dry out, go ahead and apply the sealant of choice....but don't say you weren't warned!

Why seal stone paving?

When considering slathering a stone pavement with a sealant, it's always a good idea to fathom out just why you believe a sealant is needed. "Because" is not a sufficient answer. No stone paving should ever be sealed on the grounds that it seemed like a good idea, that it's what the bloke in the pub said to do, or because spotty Darren behind the counter at the Builders' Merchant told you that's what you have to do.

Incorrectly or inappropriately applied sealants on stone paving are a regular feature of posts to The Brew Cabin discussion forum and a near-constant stream of emails.

However, if sealing is being considered because the paving is vulnerable in some way, or to improve its appearance, then it may be justified.

Vulnerabilities might be something such as being located in a damp area which makes it attractive to algae and lichens , or a north-facing site which rarely dries out, or perhaps the paving is shaded by trees which shed fruit in late summer, stain-causing leaves in autumn or bird droppings all year round (if you're really unlucky, it could be all three!)

Aesthetic improvements may be to enrich the colour, or protect the stone from the effects of UV (as is the case with the dreaded black limestone ).

What to use:

One vitally important point, which makes sealing stone paving somewhat different to the sealing of other surfaces, is that nearly every professional installer worth their salt would advise the use of an Impregnator rather than a Coating or Surface Sealer. Coatings tend to give a basic surface film which is not primarily designed to penetrate the body of the stone but to give a nice, shiny, glossy sheen, because that tends to be what Joe and Jo Public expect from a sealant, whereas those in the know understand that the best sealants work, and protect the stone, by lying just below the surface.

However, most impregnators have little or no effect on the appearance of the stone, so if you're looking for colour enhancement, you may need to use a specialist Colour Enhancer first, or opt for the coating and accept that you'll have to re-treat every couple of years or so.

More on Impregnators and Coatings

The so-called 'shortlist' of sealants that seem to perform better than most, based on the personal experience of pavingexpert.com and trusted contractors, is given on the main Sealants page .

We always like to hear about successes and failures so we can alert other site users about what to use and what to avoid, so get in touch with your experiences - and send photies!

An extensive independent and impartial trial featuring 24 different sealants has been carried out by pavingexpert.com.

The procedure and results can be read starting at this page - Sealant Trials

What to expect:

Whenever sealants are used with paving, the fact that undoing any application which hasn't quite worked out has hoped is a thankless or impossible task should be borne in mind. However, with stone, the visual effect of a sealant can be far more dramatic than is the case with concrete products or clay pavers.

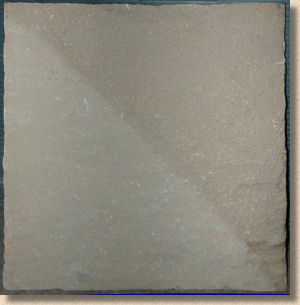

The image of black limestone above shows just how radically the appearance of a flagstone can be altered once a sealant is applied, so, even if the use of a sealant can be justified, its impact on the look and styling of the stone must be thoroughly considered before committing to apply. Test on a sample piece of stone or a discreet corner, because once it's on, it can be damned hard to get off!

It's important to understand that the nature of the stone will have an enormous effect on the finished look. While the effect on stone such as black limestone or Fossil Mint sandstone can be dramatic, on some honed granites, and on travertines and pale limestones, it can be almost impossible to detect that a sealant has been applied at all.

This is at least partly explained by the porosity of the stone, which also impacts on coverage rates as discussed below . On some highly porous stone, such as Mint Sandstone or Portland limestone, the paving will seemingly drink the first coat of sealant - it will literally sink into the body of the stone as soon as it is applied - and so multiple coats may be required to achieve the desired effect, while with more impermeable stone, such as certain granites and most types of slate, the sealant will simply sit there, on the surface, and will cure in-situ with little or none being absorbed by the stone.

Coverage:

This is determined partly by the viscosity of the sealant being used, partly by the solvent used, but the key contributory factor is the nature of the paving itself, and just how absorbent it is. Some stone is naturally more absorbent, or porous, than others. A sandstone is usually more porous than, say, a porphyry, which is usually less absorbent than a granite, but the finished texture of the stone will also have an effect on porosity/absorbency. For example, a honed or polished flagstone will usually be less absorbent than riven or bush-hammered flag of the very same stone.

As a rough guide to porosity/absorbency, put a few drops of water onto a dry surface. On highly absorbent pavings, the water will disappear in a minute or less, while on less absorbent materials, the drops may hang around for 3 or 4 minutes, or even longer. This simple test is a good indicator of potential coverage rates for sealants, as the more porous or 'thirstier' pavings will require more sealant per unit area than the less porous types. In fact, some of the highly porous sandstones will need two or three coats of sealant to achieve a suitable finish.