Introduction:

Polymeric mortars are increasingly regarded as the simplest option when it comes to jointing a residential patio, pathway or courtyard. They are fast, clean and simple with a working life of several hours and a forgiving nature for those who are not familiar with pavement jointing.

The original 'first generation' polymerics were Wonder Materials at the time, but compared to the latest materials, they were pretty basic, being dry, brush-in and leave products which never really went rock-hard nor did they bond to the paving. they were' gap fillers'. The best of the current crop of polymerics work best with wet conditions, so they could have been made specifically for the British and Irish market, they bond to the paving, they set solid and partial packs can be stored for re-use at a later date.

Jointex range:

Jointex has been a leading jointing material manufacturer in Europe for many years and they have now teamed up with McMonagles , one of the most experienced jointing distribution networks in Britain and Ireland, to make their range of products available on this western edge of the continent. There is a full range, from the simple polymerics considered on this page right up to high-strength, commercial epoxies suitable for heavily trafficked city centres and retail sites.

There's also a range of weed-resistant jointing sands for block paving and close-jointed flags.

Jointex Easy is the most popular product of the range, being a straightforward polymeric which is ideally suited for patios, paths and other pavements with no vehicular traffic. When used 'wet' it leaves behind little or no residue, just perfectly filled, neat, tidy, tough and stain-free joints with a natural colouring and fine texture.

How to use:

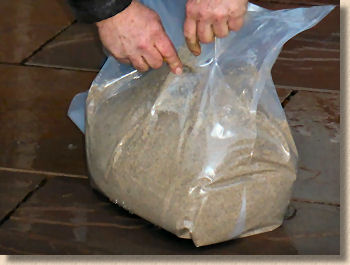

Jointex Easy comes ready-to-use, fully mixed and rarin' to go in 25kg pails with a sturdy steel 'Comfy-Grip' handle. Each pail contains the jointing mortar inside a vacuum-sealed polythene bag. Once the mortar is exposed to the air, it begins to cure, so packs should only be opened when they are to be used more or less immediately.

To minimise staining and to make the mortar easier to sweep into the joints, the entire surface of the paving that is to be jointed should be pre-wetted, given a generous soaking with clean, cold water before applying the Jointex Easy . The empty joints need to be at least 6mm (¼") wide and 20mm (¾") deep. They should be clean and free from any loose material or litter. Power-washing prior to jointing will help remove any deleterious material *and* pre-wet the surface.

The polythene bag is removed from the pail, cut open, and the mortar emptied out onto the wet surface. It's then simply a matter of using a soft brush or a squeegee to move the mortar across the surface and into the empty joints.

Sweep off any surplus as the joints are filled and progress across the pavement until all the joints are filled. Any mortar left over when all the joints are filled can be returned to the pail and, as long as it is completely covered with water to exclude any air (which would cause the mortar to start curing), it can be stored for several weeks and then re-used when needed.

After sweeping off most of the surplus, lightly spraying the surface after 10-15 minutes will help ensure the mortar is fully settled into the joints, and then a thorough final sweeping, using more water if thought necessary, to remove any last remaining grains of mortar should be carried out to complete the job. Make sure all the joints are a full as possible during this final sweep. There may be some slight settlement, a millimetre or so, as the Jointex Easy cures over the next 24 hours, but as long as the joints start out fully filled, any such settlement will be barely noticeable.

It's worth noting that, if preferred, this final wetting to clean can be omitted and the final sweep-off done dry. This is often a strategy used on sites where the drainage isn't good or where water access is limited. It won't adversely affect the long-term performance of the mortar but, in a few cases, it can result in a temporary residue or shiny 'film' to remain on the paving for the first few days or weeks following installation. This residue should weather away in a relatively short time.

The filled joints can be tooled, if desired. Some people prefer the look of a half-round or struck joint in place of the standard swepth finish, but it's purely personal taste. Tooling or striking the joint might improve the appearance (according to some) but unlike cement mortar, it makes no discernible difference to the long term performance or longevity.

Finished job:

Benefits:

- Ready mixed, vacuum packed and ready for immediate use

- Available in three colours natural sand (white lid), stone grey (grey lid), and basalt (black lid)

- Permanently water permeable

- Prevents weed growth

- Resistant to pressure washers

- Ideal for concrete or stone paving

- Suitable for pedestrian traffic

- Suitable for joints from 6mm wide and not less than 20 mm deep

Video:

Contact and further info:

Jointex products are available from a nationwide network of distributors, but if you have any problems finding your local stockist, you can contact the main stockist using the details below:

McMonagle Stone

Mountcharles

Co. Donegal

Ireland

UK - 07580 114 142

RoI - +353 (0)7 4973 5061