Can I use permeable resin jointing mortars with paving laid on an impermeable bed of mortar?

Introduction:

Note: this article refers only to Two Part (2K or Two-Component) resin jointing mortars.

Most of the One Part mortars (1K or polymerics, as they are sometimes known) are air-cured and therefore need any water that has been used to wash-in the mortar to be rapidly drained away to allow the curing process to commence.

Should an impermeable bedding material cause the wash-in water to remain within the joint, it could delay and/or impair the essential curing process. Consequently, we recommend that the One Part products (polymerics or 1K) should only be washed-in when the bedding is known to be permeable and/or very free-draining.

The background:

When it comes to jointing, we now have over two decades of Europe-wide experience using good quality, two-component resin mortars with permeable, impermeable, or near-impermeable paving, whether that's granite flagstones, porphyry cubes, basalt setts, concrete slabs, and so much more. These materials are, in some cases, laid onto a mortar, either a standard sand/cement mortar, a coarser grit/cement mortar or, more correctly, a highly permeable grit-based mortar.

Most concretes and stones are slightly permeable - that's why they look damp long after the rain has stopped. Porcelain and certain clay pavers are, to all intents and purposes, impermeable, so may require further consideration. However, the sand/cement mortar bedding most commonly used when laying paving is, more or less, impermeable*, yet we have countless examples of natural stone and other materials that have subsequently been jointed with a good-quality permeable two-part resin mortar and have continued to function without a problem.

* There is a growing trend to use highly permeable bedding mortars, but, for now, most installations are still laid on only-slightly-permeable mortars of one form or another.

It's accepted that this absence of problems, particularly in Britain and Ireland, is due in no small part to the fact that we don't get severe, prolonged, deep and hard frosts. Any frosts we get are relatively minor and short-lived, and rarely have the duration to adversely affect paving. This is why we are able to lay paving differently in Britain and Ireland, why we don't need the deep frost-cover protection that we see in northern Europe, North America and elsewhere.

The Physics:

With most residential paving having a typical depth of 20-60mm, and joint widths of just 5-12mm, there is precious little jointing material to be affected by any sustained freeze. Any frost-induced expansion is so minimal, it exerts practically no pressure of significance onto the adjacent paving.

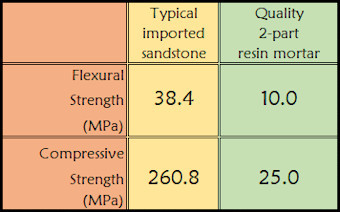

Further, the compressive strength of the resin mortar is much lower than that of most stones so, if there was to be an exceptional frost, it would be the mortar that is "squeezed" and not the paving.

When water freezes solid, it expands by around 9%. This expansion is the cause of frost heave, the phenomenon that lifts paving from the ground and is thought, by some, to cause failure of permeable jointing products.

If a joint was 10mm wide and 20mm deep, filled entirely with water, we could expect a deep frost to create a 'plug' of ice that could be 10.9mm wide and 21.8mm deep at most.

However, such a joint is NOT completely filled with water. It's mostly filled with aggregate and resin: the jointing material. For most two-part resin jointing mortars, a reasonable estimate would be that roughly 70% of the joint volume is fine aggregate and resin: only 30% can be water.

So, if we have only 30% water, the frost expansion can only be 30% of what it might be in a water-filled joint, so, instead of 10.9mm width, a frozen joint could only be a maximum of less than 10.3mm - just a third of a millimetre of expansion.

Further, when the edges are fully constrained, as is the case with most paving joints, the pressure exerted by a freeze will find the easiest outlet, and so any expansion is more likely to be upwards and out of the joint, and not sideways to exert pressure onto the paving.

Finally, bear in mind that, unlike cement-based mortars, most quality two-part resin mortars have a relatively high degree of elasticity. They are designed to be stretched and squeezed, and to recover without ill-effect. This elasticity of the mortar is relatively minimal, but it is more than enough to cope with the exertions of a British or Irish winter.

Water Penetration:

There are so many installations where quality two-part resin mortars have been used with paving having much wider and deeper joints, yet there are practically no jointing failures due to frost in Britain and Ireland. Setts may have joints that are 9-15mm in width and depths of 100mm or more, so considerably far more jointing material than patio paving, and therefore more potential for frost expansion, yet we just don't see it. It doesn't happen.

But what about water penetration? Surely that is detrimental to the performance and service life of a pavement, isn't it?

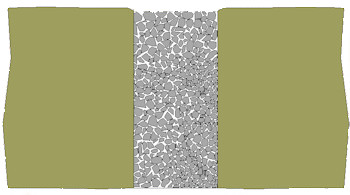

If, for argument's sake, we regard the paving itself to be practically impermeable, and the bedding (the aforementioned sand/cement mortar) is similarly impermeable, there is only the volume of the joint available to act as a reservoir for any residual surface water - less the actual volume of the jointing mortar grains, of course.

If we further assume, again for argument's sake, that 70% of the joint is filled with "solid" fine aggregate and resin, that leaves 30% void space which could, in theory, be filled with water. That's the most that can be held. Try as we might, it's impossible to get more water into that joint. Once the joint is filled with water (it's known as 'saturation') no more water can enter. The impermeable bed and the impermeable paving won't absorb any of the water (or will only absorb a negligible amount) so once the joint is saturated, no more water can enter. It's full, and cannot, by definition, be fuller.

If, as stated above, no water (of any significant quantity) is able to penetrate the bed or the paving, then it cannot cause any significant damage. All that water can do is sit there, sulk a bit, and wait to be evaporated.

Now, there are permeable paving materials. In fact, there are some materials used for paving in Britain and Ireland that have a permeability which some believe could rival a bathroom sponge, Mint and Rainbow sandstone being just two of the worst offenders. In pavements where such materials have (inadvisably) been laid, we have to accept that moisture can enter the paving material.

But, even if we were to use a totally impermeable jointing material, say thiosulphite mastic or similar, moisture will still enter the paving via the surface, and when to compare the surface area of a flagstone to the area of edge in contact with jointing material, there's far greater potential for that moisture to enter from the top, rather than the sides.

Think about our widespread use of granite, sandstone, limestone and all sorts of other natural paving materials that are, to greater or lesser extents, permeable. We wouldn't consider rejecting these materials for pavement construction simply because they exhibit permeability.

In an ideal world, paving would be laid on a highly permeable bedding and jointed with a permeable material, so all that excess surface water could be directed to ground, as happen in an open field, rather than being channelled towards a man-made drainage system and dumped directly into our streams and rivers, or, even worse, sent for expensive and unnecessary cleaning at the local Effluent Treatment Works.

For the less-than-ideal world in which we live, and given the highly variable installation methodologies which seems to be preferred in Britain, a permeable, quality, two-component resin mortar cannot damage quality paving. Poor quality paving might suffer, as might poor quality installation, but good quality paving properly installed has nothing to worry about from the use of a good quality two-part resin jointing mortar.

Preventing the problem:

The old adage about prevention being better than a cure has a lot going for it. Time and time again in the paving trade, designing, engineering, installing using methods and techniques that will eliminate a potential problem pays significant dividends in the medium-long term. This ancient wisdom holds true for rein mortar joints. A little bit of ‘engineering’ prior to applying the mortar will minimise any risk that might arise from water penetration and/or frost.

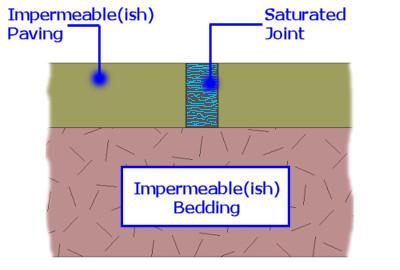

The problem identified above is that joints filled using a permeable resin mortar or compound can act as a reservoir for moisture when the bedding layer is impermeable. So, if we could somehow render that bedding permeable, or sufficiently permeable-ish to enable the jointing mortar to drain freely, the potential problem is prevented.

How to make a fairly impermeable bedding mortar permeable? Simple: Drill holes through it!

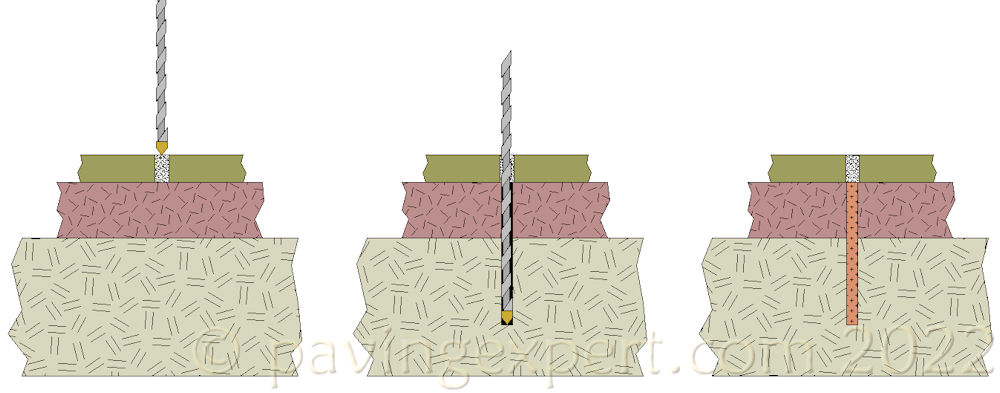

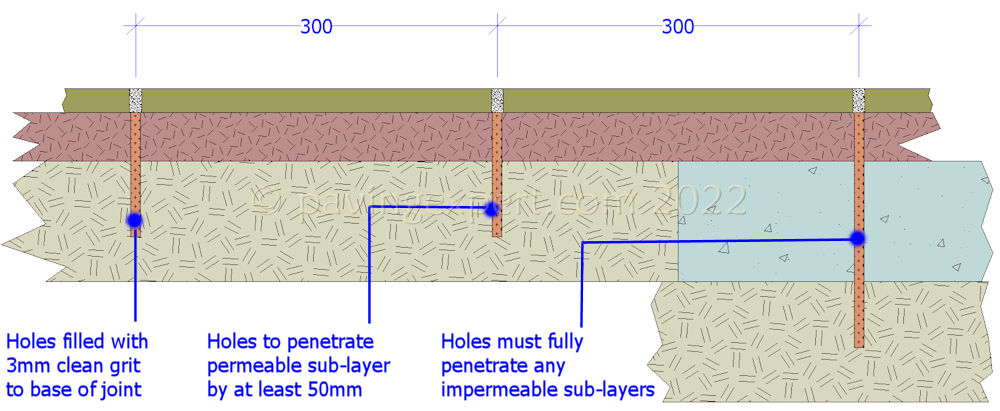

On a typical pavement of flags/slabs or setts, blocks, etc., by drilling joint-width holes through the bedding and penetrating the sub-base beneath, an escape route is provided for any moisture or water within the joint. Where paving has been laid over a bound base (concrete or macadam) the drilled holes should fully penetrate those layers also, providing a route for surface water from joint all the way to a permeable layer, whether that is sub-base, capping layer or sub-grade.

And ensure any drilled hole does penetrate the permeable layer by at least 50mm. It’s not sufficient to simply reach the upper surface of the permeable sub-layer: the hole must punch through into the permeable layer in order to increase the surface area of contact between the grit/gravel fill and the permeable sub-layer.

Imagine a 10mm diameter hole – that’s a radius of 5mm. When it’s solely the bottom of that hole in contact with the sub-layer, that’s an area of….

3.142 x 52 = 78.6mm2 (πr2)

Now, if that drill penetrates the sub-layer by just 50m, the area of contact between the sides of the hole and the sub-layer, which is an open cylinder, increases by the depth of the hole multiplied by its circumference…

50mm x (2 x π x 5mm) = 50 x 2 x 3.142 x 5 = 1571mm2 (2πr)

…which is roughly 20 times the area of the drill tip surface alone.

The holes will need to be at 300mm centres (so: 300mm or so between each hole), with a diameter as large as is possible within the joint without risking damage to the arisses of the paving, and they will need to be filled with a fully permeable material. Of course, they could be left empty and allowed to fill with the permeable jointing mortar, which is all well and good if you don’t mind throwing away good money. For those with an eye on the budget, filling the drilled holes with a 3mm clean grit or pea-gravel will work just as well.

Once the holes are filled, the jointing can be completed in the usual manner. All that is different is that, instead of the joint being a container for moisture within the resin mortar, it’s now a channel or conduit that will direct water to the exit via the grit-filled holes that have been drilled through the impermeable bedding mortar (and any other impermeable sub-layers).