Introduction:

The biggest area of growth in paving products within the British market over the last few years has been with so-called ‘Porcelain’ paving.

You may have noticed the phrase ‘so-called’ in that opening sentence, and that is a key part of the reason behind this page on the website. Not everything that is labelled as porcelain or looks like porcelain is necessarily porcelain. There are fairly nebulous definitions for what can be described as porcelain, and what ought to be labelled as ‘ceramic’ or ‘vitrified’ or some other almost-but-not-quite porcelain-ish term.

Obviously, the Good Guys at the top of the food chain in supplying paving to the British residential and commercial sectors by-and-large tend to play by the rules, and when they state their products are porcelain, that’s usually the case. However, with the market for ‘baked paving’ now being so large, a lot of lesser names, wannabe market traders, chancers, and downright rogues have decided to avail themselves of an open and pretty-much undefended market. And their primary tactic is…..how to phrase it……less than full disclosure.

Some are completely dishonest and are selling ceramics as porcelains. They lie. They state their stuff is porcelain, when it isn’t.

Others rely more on obfuscation. They cleverly never publicly state that their products are porcelain, but that they are ‘Italian Ceramics’, or ‘Top Class European Vitrified Pavings’, or claim that there is little, if any, difference between ceramics and porcelain.

What is porcelain?

Actually, it’s a bit of a nightmare trying to get an agreed definition of what is porcelain and what is ceramic, but, once you start to trawl the depths of the tiling industry, where porcelain is far, far more widely used and they have decades of experience with the material, there does seem to be some loose agreement around a particular ASTM (American Society for Testing and Materials) document that reckons that to qualify as porcelain, a tile (flag???) should have a water absorption rate of less than 0.5%.

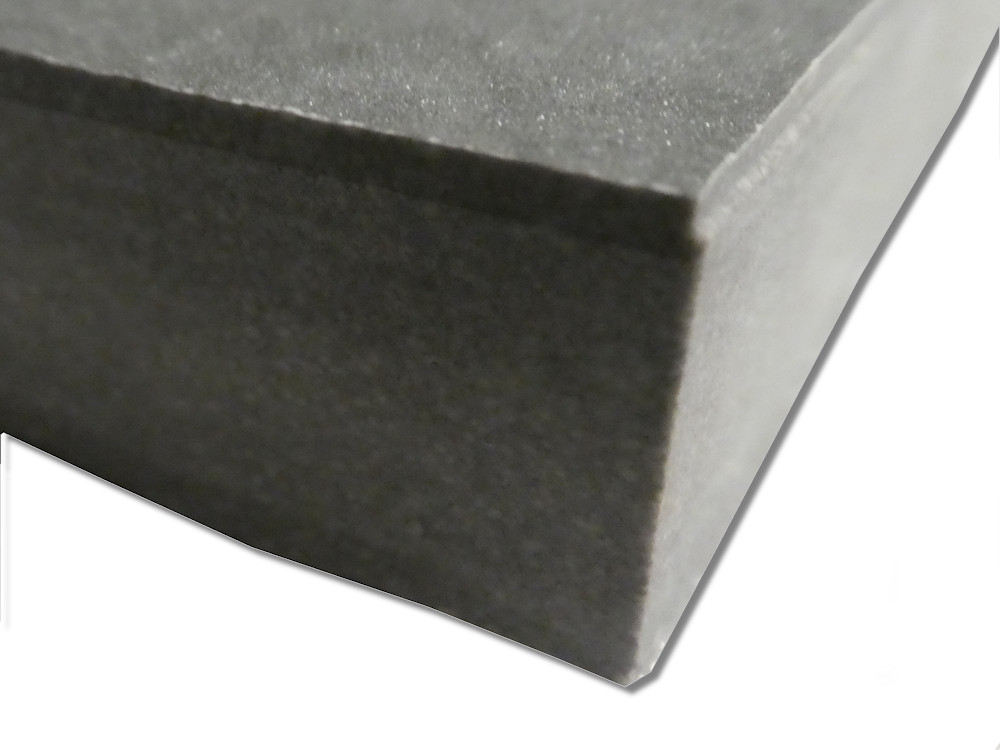

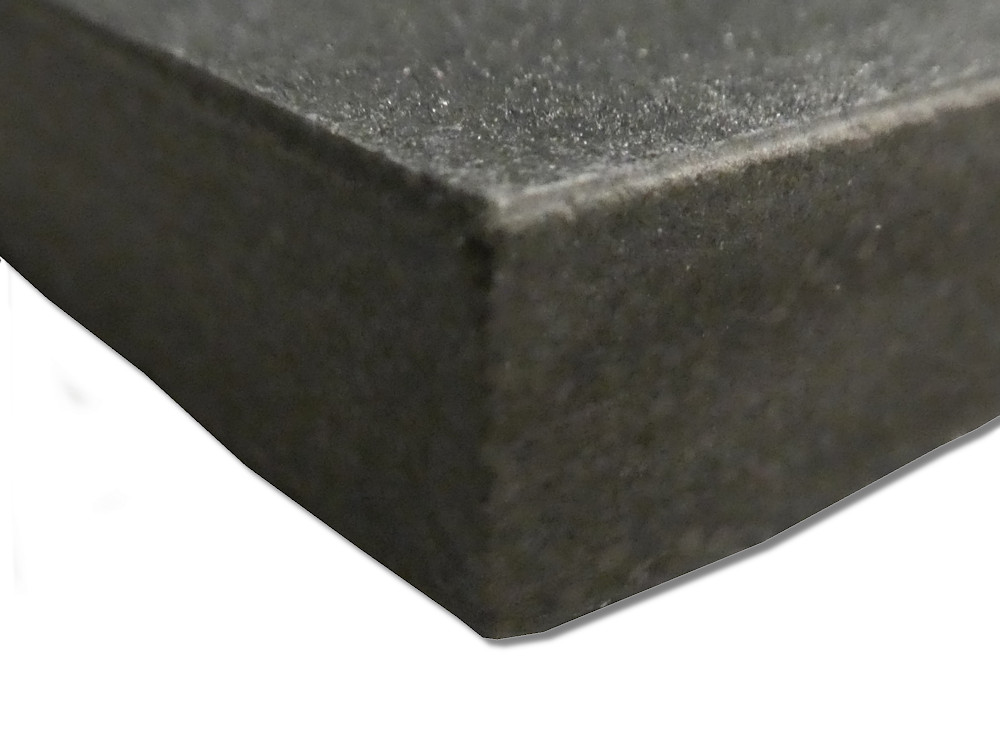

There’s also a difference in the manufacturing process between true porcelain and some ceramics. True porcelain is (usually) a blend of white clay, selected fine sand and feldspar, fired once as a biscuit, whereas ceramics tend to use non-white clays with no feldspar, and will often have a glaze applied after an initial firing, and then be fired again to ‘set’ the glaze.

There are other identifiers, such as being harder/tougher and more awkward to cut, having a higher kaolin content, needing to be rectified post-firing, and requiring a higher firing temperature*, but these can be a bit vague as some ceramics would meet these requirements, yet are most definitely not porcelain based on the water absorption criterion.

*Ceramic tiles are usually fired at 1,000°C to 1,100°C, whereas Porcelain has to be fired to 1,250°C in order to melt the kaolin component.

Which to choose?

Porcelain:

- White Clay/Ultra-fine sand/Kaolin

- Fired at 1,250°C or higher

- Usually monolithic body (no layers)

- Water Absorbtion <0.5%

- Denser than ceramic

- Damned Hard

- Brittle when cutting

- Costlier

Ceramic:

- Made with Coloured/non-white clays

- Fired at 1,000°C- 1,100°C

- May have separate glazed layer

- Water Absorbtion >0.5%

- Less dense

- Softer, but only just

- Easier to cut

- May be susceptible to hard frosts