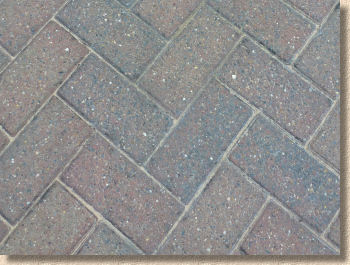

Refurbishing a block paved driveway

This page is one in a series which documents the refurbishment of an existing block paved driveway. Although the page can be read as a standalone article, it will probably make more sense if read in conjunction with the associated pages listed below.

Part 6: Re-sanding

The Problem

Although the areas that were repaired (see previous ) were re-jointed as part of that work, the bulk of the driveway has endured compromised joints since it was cleaned some days previously. Although it is unlikely that there are any truly empty joints, and despite the care taken during the cleaning process, most of the joints have been partially stripped of the critical sand jointing that gives this type of elemental pavement much of its strength and competence.

Empty joints It is important to appreciate that jointing sand is not there simply to fill the gaps between adjacent blocks: it provides the essential friction which then generates the horizontal and vertical interlock that allows those little blocks to carry such relatively big loads. Without the jointing sand, the pavement would, literally, fall apart, so it very definitely must be replaced.

Brushing-in:

Of all the tasks that form part of this refurbishment project, this re-sanding of joints has to be the easiest. The surface needs to be dry to ensure the kiln dried sand (KDS) sweeps across the blocks without getting stuck, and a decent medium bristle brush is ideal.

So, it's nothing more complicated than scattering the KDS over the dry surface and then using the brush to push it around and into all those open joints, topping them up as you go. Unlike the jointing done immediately following pavement construction, this top-up jointing will not be rattled-in using a vibrating plate compactor. Instead, we rely entirely on gravity to fill the joints, but bear in mind that, by and large, the joints are already filled to half or two-thirds depth and this exercise is merely topping-up, so no great effort is required.

The sand will trickle into the joints and then it's just a matter of sweeping off the excess. It's virtually impossible to remove every last grain of surplus sand, so there's no need to obsess. As long as the bulk of the excess is removed, the weather and traffic over the next day or two will settle it into the joints and blow away most of the leftovers. And, as we shall see in the next section , we have a tactic to remove the last few dregs that remain prior to the sealing.

The joints should be visibly full and there should be no significant quantity of sand on the block surface.